3D wall panels

In the design of modern interiors, it has become popular to use 3d panels. Such a wall covering creates a room with a presentable appearance, while the installation system is not anything complicated. In the article, we will consider a variety of 3d wall panels.

Advantage of 3d wall panels

- Modern production technologies make it possible to create universal and exclusive materials. 3d panels are square or rectangular slabs. Sizes vary and are often made to order.

3d panels photo

- The basis of the three-dimensional coating can be made of MDF, gypsum or bamboo, which contributes to easy, and most importantly, durable attachment to the walls. At the same time, during installation, the risk of cracks or any deformation is almost minimal.

- The slabs themselves have a three-dimensional ornament or a holistic pattern. The use of 3d panels for wall decoration helps to give the home a truly exclusive design. The facade of the walls can look like a natural material, a surreal landscape or simple smooth lines.

- There are a number of positive points that are of significant importance in favor of 3d panels, namely:

- Numerous mounting options. Depending on the construction skill, you can individually choose the method of fastening, whether it be glue or auxiliary guides. In the first case, the repair is significantly accelerated, and in the second, time is saved on leveling and puttying.

- High level of wear resistance. 3d panels are often used for rooms where a large number of people are expected to be constantly present. They are easy enough to care for, especially if there are small children in the house. In addition, walls with a similar finish are not afraid of direct sunlight.

- The specificity of the external design is so interesting that depending on the lighting or the angle of view, the pattern may change.

- Wide range of colors and textures. With the help of bright contrasts in 3d panels, you can make any accent on the interior of the room. Or vice versa, smooth out the tones with the help of bed flowers. Therefore, this design is gaining more and more popularity, as it helps to solve any design idea.

- Environmental Safety. The production technology of this material is based on no harmful substances. Therefore, during operation, the panels do not emit toxic fumes, which means that they can be used in homes where there are children or people suffering from allergies or other respiratory diseases.

- Depending on the possibilities, you can purchase panels that already have a finished finish, or opt for the option of primed panels. They, in turn, will require a number of works (painting, plastering, veneering, etc.).

- 3d wall panels allow you to additionally insulate and isolate surfaces from extraneous sounds. And all due to the fact that such plates have a fairly high density, which in turn affects the resistance to mechanical damage.

- Possibility to install even on uneven walls when mounted on drywall profiles or wooden slats.

Types of decorative 3d panels

Today's market offers several variations of 3d wall panels.

Plastic 3d panels

- This option is great for those who do not have too wide financial opportunities. But this does not mean that such panels will be of poor quality.

- This decor most often imitates tiles, bricks or various fabrics. A huge advantage of plastic 3d panels is their light weight, due to which it is easy to carry out installation work with them.

- In addition, plastic has good water-repellent properties and is easy to clean up.

3d mdf panels

- The plates are produced with a relief pattern, as well as having an MDF base, which is sprayed with various chemical compositions.

- If you have the funds, you can opt for panels covered in leather or suede. But, in the latter case, it must be taken into account that they will require rather complex care.

3d veneer panels

- For lovers of natural products, lamellas made of stained or lacquered veneer are suitable. This texture creates a rather refined room, although its cost is significant.

3d eco panels

- If there are doubts about the toxicity of the material, then you can opt for bamboo 3d panels.

- The production technology involves grinding this plant, after which the necessary relief pattern is made from the resulting mass by means of special forms.

3d gypsum panels

- This type of plate is convenient for seamless installation. In order not to see even the slightest joints, putty is used, after which the evenness of the entire surface is given with sanding paper. Next, the walls are painted, and all the seams simply become invisible.

- They look great in any interior, and if desired, they can be repainted in any color, creating new images.

- During installation, it must be borne in mind that gypsum is a fragile material. It must be fastened carefully so that the head of the self-tapping screw does not deepen, but is flush with the surface of the plate. Also, these plates cannot be supported at an angle, as this leads to chipping of the material.

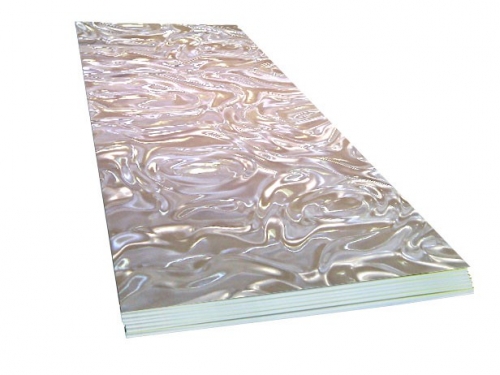

Glass 3d panels

- The average thickness of such a sheet will be 0.5 cm. For the manufacture of this type, tempered glass is used, which has increased strength. Even if it breaks, the fragments will look similar to the fragments of an automobile windshield, that is, without sharp edges. Therefore, if such a nuisance occurs due to the fault of the child, he will not be cut.

- Glass 3d panels in the interior create a feeling of lightness and airiness of the room. Their most beautiful use for the design of private pools.

The concept of 3d panels is found not only in the names of materials for the interior lining of an apartment or house. On sale there are galvanized 3d panels, which are fence sections. They are popular for fencing sites, both in the city and in private country houses.

3D panel manufacturers

The scope of relief wall panels is quite wide. Three-dimensional materials are used both as a basis for the entire interior and as an accent for any particular detail, such as a painting.

It is not difficult to buy 3d panels, as there are many well-known companies that produce them. But due to the growing demand for this facing material, many private manufacturers have appeared who offer their products under unknown brands.

The most popular manufacturers in the modern market are:

- artpole. The panels depict a ready-made drawing or are the basis for individual painting.

- Leto. An Italian manufacturer that focuses on a novelty in this area - luminous 3D panels. The lighting system operates on the principle of phosphorus, that is, it accumulates ambient light, and when it is dark, it begins to give it away.

- meister. This company has developed a special mount - a double groove. Thanks to this, the plates can be mounted on the wall in several tiers, due to which a more effective three-dimensional image is achieved.

- Wallart. They specialize only in environmentally friendly plates, that is, from bamboo. The production technology provides geometrically correct shapes and airtightness of the plates. When decorating the interior, there is always the opportunity to paint them in any color, as well as open them with varnish for extra shine.

On average, the price of a 3d wall panel varies from 2500 to 6000 rubles/m2.

3d panels in the interior

Thanks to the development of the repair industry, volumetric slabs have acquired a variety of design forms. This contributed to the fact that this material has found wide application in interior decoration, namely:

- the ability to create absolutely any imitation: metal carving, texture of precious wood, marble imitation;

- professional designers, using 3d panels, divide the living space into different zones, while maintaining a holistic image of the room;

- with the right choice of texture and color, this finish visually enlarges a small space;

- due to 3d material, you can focus on certain interior details, as well as divert attention from unnecessary things;

- ease of implementation of their creative and design ideas.

Technology for the production of 3d panels

Not only the appearance of the finished product, but also the quality of its operation depends on compliance with the features of the technology.

- The first step is to develop a panel design project. A team of specialists creates a sketch of the future drawing. For this, modern computer technologies are used, due to which, focusing on modern trends, a three-dimensional panel pattern will be developed.

- Next comes the production itself. At this stage, work is underway related to giving relief to the plane. For this, special equipment is used. In more expensive brands of 3d panels, the finishing points are completed manually by craftsmen. But only when the work is on an exclusive order, in all other cases, the machines work.

- Finishing work. The final step is always lining. The panel can have a glossy, matte, "metallic" or fluorescent surface. Special coatings are also used that protect the material from mechanical damage, moisture and direct sunlight.

Technology of mounting 3d panels

Despite such an exotic material, it is not difficult to work with it, the main thing is to be careful. If one of the sheets is damaged, then this will disrupt the entire drawing and then you will have to additionally buy an expensive structural element.

Calculation of the number of 3d panels

Depending on the type of panels chosen, completely different amounts of material may be needed. Each 3D sheet has its own parameters, based on which, you should focus on the amount of decor you need:

- glass models have a thickness of 0.5 cm and dimensions of 60x60 cm;

- plaster models have dimensions of 60x60cm and a relief protrusion of 1-6cm, the thickness of the slabs is from 0.4 cm to 0.6 cm;

- bamboo models have an average value of 50x50cm, thickness - 1.5-1.7cm. sale is carried out in packs of 6 to 44 pieces.

But all the above parameters are averaged, so you should not get attached to them. Nevertheless, in order to calculate the necessary material as correctly as possible, it is better to contact specialists. Next, consider the mounting methods.

- Fastening to the crate. When installing 3d panels, there is always an air gap of 3-5 cm. It can be usefully used for wires and cables, although at first glance it may seem that the living room has decreased somewhat.

- Self-tapping fastening. The part of the panel, which has a guide with grooves, is attached to the wall with self-tapping screws. After that, the second part of the structure is applied to the first until it clicks. Thus, all panel elements are mounted. If a pattern is expected, its joints and contours must be controlled. The convenience of such fastening lies in the fact that the evenness of the wall is not fundamental here, because all the flaws will hide inside. Also, in case of damage to any part, it will be easy to replace it with a similar one.

- Gluing. If the base surface is flat and does not have bumps or depressions, then installation can be carried out by gluing. To do this, you need "liquid nails" and a notched trowel. The solution is applied evenly over the surface of the wall with a spatula. After that, the plates are fixed on it, and hold on until they “grab” the surface. If excess glue protrudes through the seams, they must also be carefully removed.

It is worth noting that before you engage in installation work, you need to take care of the working surface. After all, the 3d panels themselves are not cheap and poor-quality work, threatens at least a short service life, and as a maximum - additional financial investments. For example, in order to reduce the consumption of the adhesive composition, which also does not differ in low cost, it is better to level the walls in advance. To do this, you can use plaster or drywall.

Both methods are suitable for fixing three-dimensional plates to the ceiling. But experts recommend using self-tapping screws before the material is glued to the solution.