Do-it-yourself laying of paving slabs and paving stones on a concrete base

Laying paving stones is an excellent solution for improving the local area, garden landscape and arranging a recreation area. You can perform paving with paving slabs on your own - the technology is quite simple and does not require the use of professional equipment. Knowing some of the nuances of working with a concrete base, it will turn out to create a beautiful, durable and wear-resistant coating.

Paving slabs on concrete: "pitfalls" of laying paving stones

As a finishing material for country houses, summer cottages, sidewalks, paving sites, gazebos and patios, many people prefer to use paving stones. Paving slabs are optimally suited for these purposes due to their performance characteristics:

- resistance to temperature fluctuations and the possibility of using lining in regions with a harsh climate;

- frost resistance - high-quality tiles can withstand up to 300-400 freeze / thaw cycles;

- high strength of the finishing material - up to 300 kg / sq. ft.;

- environmental friendliness of concrete pavers - when heated, the slabs do not emit toxic substances, unlike asphalt

- puddles do not form on properly laid paving stones after rain - water is absorbed into the ground through cracks and storm drains;

- aesthetics and decorativeness of the coating - today manufacturers offer a wide range of models of different colors, shapes and textures;

- ease of installation - it is not difficult to lay paving slabs with your own hands, the main thing is to choose high-quality material and adhere to technology;

- the service life of pavement coating is about 15 years.

The use of tiles of various shades, the play of a textured surface, laying according to interesting patterns like a mosaic will enliven the landscape of the garden and the local area. In addition, working with paving stones will allow you to maximize the talent of the designer and the artistic taste of the performer.

Traditionally, paving stones are laid on a gravel-sand base, placed directly on the ground. This option is considered to be simpler. In areas with high traffic or for parking arrangements, a reinforced base is required to provide reliable coverage. In these cases, it is desirable to lay the tiles on concrete.

The technology of laying paving stones on a concrete base has its own characteristics:

- The tile is laid out on an even prepared base - this ensures the stability of the finished coating. Even under the influence of regular mechanical loads, the tiles will not sag, and the tracks will not lose their original configuration.

- During installation, drainage and drainage must be ensured so that water does not stagnate on the tiled floor. If this requirement is neglected, then moisture accumulates in the tile joints, and when freezing, ice particles gradually tear off the finish from the base and, as a result, individual fragments swell and split along the edges.

Important! When pouring concrete, special attention is paid to water disposal. Experts recommend creating storm drains, point moisture collectors, or laying a coating with a slight slope.

Features of the choice of paving stones

When planning to lay tiles with your own hands, you should have an idea of what types of paving stones are and how to choose the right facing material.

Before buying, you need to decide on the main parameters:

- plate material and purpose;

- method of manufacturing paving slabs;

- shape and size of paving stones;

- quality characteristics of the tiles.

Depending on the raw materials used in the production, paving tiles can be: rubber, wood, stone, clay and concrete. The choice of material is largely determined by the scope of use of paving stones:

Modern paving stones are produced by one of the methods: vibrocasting or vibrocompression. This or that method determines the strength characteristics of the coating.

Features of paving stones produced by vibrocasting:

- the main purpose is paving areas that are affected by small loads;

- insufficiently accurate geometry of individual plates;

- clarity of the applied image on the paving stones;

- a wide selection of a wide variety of colors;

- Great for arranging garden and country paths.

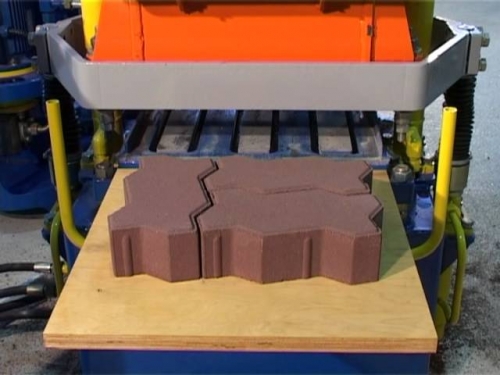

Plates made by vibrocompression:

- used for paving sidewalks, parking lots and roads;

- has high strength;

- issued in simple forms;

- limited color choice.

Most manufacturers produce paving stones in the form of hexagons and classic paving stones. Some companies produce the so-called "herringbone", "wave" and "rocket". The most convenient and versatile option is a rectangular tile. With its help, it will be possible to create patterns that imitate brickwork, "ladder" and "chess".

Important! To work with paving slabs of complex configuration, you will need to create or order a design project.

An important selection criterion is the size of the tile. The smaller the dimensions of the individual elements, the more efficiently the load is distributed. For laying straight paths, the size of the tile does not really matter, but for paving arcuate terraces, it is better to use small paving stones. Circular figures are laid out with specially designed paving stones.

When buying, you need to check the product quality certificate and find out the main characteristics of the tile:

- number of defrosting/freezing cycles;

- paving stone thickness (4 cm - for pedestrians, more than 6 cm - bicycle paths, 7-8 cm - for vehicles, 10 cm - truck traffic).

Advice. You can judge the quality of a tile by its sound. To do this, gently tap the tile on the tile. A sonorous sound means high-quality drying and material strength. Deaf, on the contrary, indicates that the technology was violated during production.

Rules for paving paths with paving slabs on concrete. Expert advice.

Ways of laying paving stones on a concrete base

Paving on concrete can be carried out in one of the following ways: on a dry cement-sand "cushion" or on a prepared grout.

Do-it-yourself tile laying (step-by-step instructions are shown in the photo).

The first method provides for the device of carving from dry materials with a thickness of about 6 cm. The paving stones are tightly laid on the “cushion”, and the seams between the slabs are covered with a cement-sand mixture and watered. The procedure is repeated several times.

The second option provides durable and strong paving. However, when laying tiles on a concrete mortar, the coating after deformation cannot be restored.

Laying paving slabs with your own hands: step by step instructions

Tools and materials

For paving the path you will need the following materials:

- paving stones - purchased with a small margin;

- curbstone;

- crushed stone fraction 10-20;

- sand;

- cement;

- water;

- crosses for styling.

From the tools you need to prepare:

![]()

- bayonet shovel;

- cord;

- concrete mixer or drill with a mixer nozzle;

- level;

- rubber mallet;

- Master OK;

- grinder for cutting plates;

- level for horizontal control;

- rule long and short;

- country rake;

- hard brush.

Marking and preparation of the site

Preparatory activities include:

Preparation and pouring of concrete solution

When mixing the solution, it is important to observe the exact proportions. To create a base for paving stones, 1 part of cement and 3 parts of sand is taken. The mixture should be quite liquid in consistency, resembling thick sour cream.

Concrete pouring procedure:

Important! When concreting a large area or a long path, expansion joints with a width of at least 5 cm are left every three meters.

Tiling order

With high-quality preparation of the concrete base, there will be no problems with laying paving stones. Installation of paving stones starts from the curb. Laying is carried out in the direction from top to bottom towards the water outlet.

Apply a mortar with a thickness of about 3 cm to the concrete and proceed with the layout of the material. Paving technology is in many ways similar to laying tiles on the floor with your own hands. To maintain the same distance between the paving stones, you can use plastic corners of 4-5 mm. The location of the laid tiles must be leveled with a rubber mallet. Check horizontality with a level.

Fill the gaps between the paving stones with sifted sand, sweep the excess with a broom. Pour the finished coating with water. If necessary, sand the joints again and moisten.

Do-it-yourself tile laying: step by step instructions. Video

The nuances of laying paving stones on an old concrete base

If there are old concrete paths in the yard, then they can be radically modernized and paving with paving stones. However, this method is acceptable for coatings that do not have significant defects.

Tiling algorithm:

- Assess the condition of the coverage.

- Remove debris, sand particles, greasy stains and chipped concrete fragments from the track.

- Remove bumps, cracks, and putty cavities.

- Apply a tile adhesive designed for outdoor work to the surface.

- Perform the layout of the paving stones.

Laying paving slabs with your own hands: video.

Paving stones on a country plot: photo ideas

Access road to the house, paved with paving slabs of classical rectangular shape.

![]()

The combination of two contrasting colors of paving slabs of complex shape.

Multifaceted paving using paving stones of different colors and shapes. It is better to entrust such work to professionals.

Laconic design of the bathroom with the use of stone slabs. The different widths of the tile joints emphasize the natural style and make it easier to lay tiles in the bathroom with your own hands.

An interesting ornament of the path adjacent to the house emphasizes the architectural style of the house and the landscape design of the suburban area.

Do-it-yourself tile laying: video