6 options for flooring your terrace

Before starting work on paving the floor, it is important to make sure that the reinforced concrete slab of the terrace is made with a slope of 1-3%. For some materials, this figure is higher. Of course, the descent should be located in the direction from the house, and the floor level of the terrace should be lower than the floor level in the house. You can perform the ramping from mortar, concrete or polystyrene foam wedges.

The material that is supposed to be used for the flooring of the terrace must necessarily meet the following requirements.

- • Frost resistance. This term is understood as a low percentage of moisture absorption (up to 3%), which determines the resistance of the material to repeated freezing and thawing. Information about the characteristic is on the packaging, more often in the form of a snowflake.

• Resistant to abrasion from heavy use and abrasive sand. The indicator determines the aesthetic qualities of the coating, after several years. For stone and wood, this is not the main characteristic, but if we talk about ceramics, then the abrasion class must be at least 4.

• Anti-slip properties ensure safe movement. To indicate this characteristic, the marking "R" is used, for terraces the minimum requirement is R9.

Additional protection must be provided to the wall that is in direct contact with the terraced floor. To do this, it is lined to a height of 15-20 cm from a similar or similar material, and the upper edge of the base is treated with sealant, acrylic or silicone.

Another important point is the presence of expansion joints. They absorb the difference in expansion coefficients of different materials. The gap of 1-2 cm between the floor of the terrace (including the slope-forming layer) and the wall is filled with any elastic material.

In order to compensate for temperature deformations, such joints should also divide the flooring of the terrace into rectangles and squares and be located every 2-5 m. The higher the thermal effect on the terrace, the smaller the step. The seam is filled with an expansion cord, over which silicone grout is applied.

Terrace ceramic surface

Ceramic flooring products are distinguished by a wide range of colors, a large number of shapes, sizes and textures, which makes it possible to create an original design and makes them the most popular option. For terraces, ceramic and clinker tiles are used.

Porcelain stoneware or gres tiles differ from ordinary ceramics in increased strength and frost resistance. The optimal size of such tiles is 45*45 mm or 30*60 mm. On sale are presented with a polished and unpolished surface. Unpolished is preferred. It features anti-slip properties and high durability. A uniform cross section allows such a coating to maintain its original appearance even with slight abrasion.

Clinker tiles are ideal for terrace floors due to their resistance to abrasion, moisture absorption coefficient of 0.5-0.7% and durability. It is made from clay, therefore it is presented in brown, red and red shades. If the surface is glazed, then the color range is wider. The anti-slip effect corresponds to the marking. As for the dimensions, the thickness of the tiles is 10-16 mm, the width is 11-31 cm, the length is 24-31 cm.

Features of laying ceramics

If the tile is laid in a pattern, then you need to start work from the most noticeable place. The tile is glued to the base with a special adhesive mixture, which is applied with a notched trowel, both on the base slab and on the tile.

In order to prevent excessive drying of the solution, it is distributed over an area of no more than 1 m2.

The seams are made using crosses (5-10 mm.) And overwritten a few days later, after the adhesive mixture has completely dried. The mass of the grout should be for outdoor use, elastic, with increased adhesion, and quickly set.

To avoid the appearance of persistent stains, all dirt on the tiles and grout that occurs during work is immediately removed with a damp, and then dry, sponge.

Advantages

- • Easy care

• Affordable price

• Constancy of quality characteristics and color.

Flaws

- • Heats up and stores heat.

• Seams require extra care.

• Plaque appears on clinker tiles over time.

Natural stone flooring

Looks most harmonious in a natural environment. However, not every stone is suitable for a terrace. The best option would be a tile made of selenite, basalt or granite. Sandstone, travertine and limestone will be completely inappropriate.

The texture of a stone slab can be: burnt, bush hammered, chipped, polished, polished or sawn.

Styling features

The elements are laid in the same way as ceramic tiles, with the difference that the stone requires a higher surface slope of 3-5%. Stone slabs are glued with special glue for stone made of white cement, on the most even surface. The adhesive mixture is applied to the lower surface of the tile and to the concrete base, with a layer of 4-5 mm. The thickness of the seams is at least 5 mm. After laying, the seams are rubbed. The composition of the grout should include silicone. After the completion of the paving work, the floor covering is covered with special preparations that protect the stone from contamination, reduce the moisture absorption coefficient and make the surface harder.

Advantages

- • Excellent technical qualities.

• High strength and durability.

• In the process of aging becomes even more beautiful.

Flaws

- • The color of the stone often does not match what is expected.

• Heats up quickly in the sun.

• Breakage possible with strong impacts.

• Requires additional care (periodic impregnate treatment).

• Seams get dirty quickly.

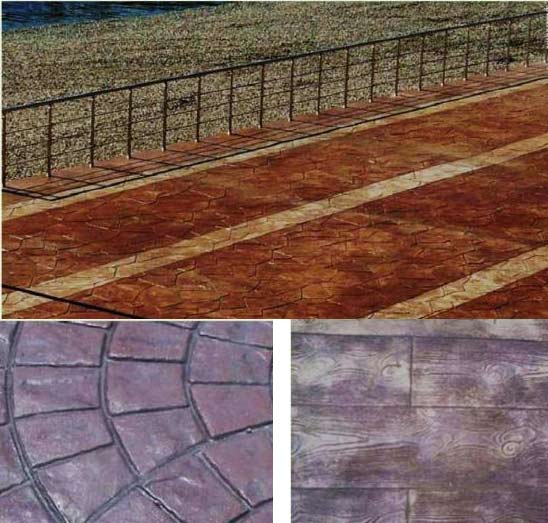

Decorative stamped concrete

A special mortar is laid on the reinforced concrete base, sometimes with the addition of coloring pigments and processed with patterned or textured forms.

stamped concrete on the left-bottom imitates granite paving stones, on the right-bottom deck board

As a result of stamping, imitation of stone, sandstone, pebbles, paving stones, boards or bricks is possible. The thickness of such a coating is 10-60 mm. The screed requires a level, stable concrete base, minimum class B25, with a slope of at least 2%.

Styling features

The work begins with the laying and ramming of the fiber-reinforced concrete. The coating is leveled with a hardener, rubbed and stamped with the necessary pattern. An expansion joint separates sections of 3*3 m. After removing the formwork, the coating is covered with acrylic impregnate. A month later, the expansion joints are filled with a highly elastic material. If the layer of stamped concrete is 10-12 mm, then reinforced concrete slabs are pre-coated with an adhesive layer.

Advantages

- • Minimum amount of work.

• Excellent imitation of the selected material.

• Lack of seams.

Flaws

- • Coating may have reflections.

• Every 2-3 years requires treatment with protective compounds.

• Gets very hot in the sun.

Concrete tiles as flooring

Finished products are produced by vibrocasting or vibrocompression. They can be with a smooth or rough surface, imitate natural stone, paving stones, wood, ceramics. The thickness of such tiles is 38*45 mm, the sizes are usually 60*60 cm, 60*45 cm, 30*30 cm and 60*30 cm. In addition to rectangular shapes, decorative elements are made, which allows you to create a complex ornament.

Styling features

Paving concrete tiles, similar to gluing stone slabs. The work uses special adhesive mixtures (not for stone), which are applied pointwise or evenly distributed over the surface of the tile and base. During laying, the tiles must be tapped with a rubber mallet, thus distributing the adhesive mixture. The thickness of the seams is 4-10 mm. For grouting, an elastic mass for stone is used. The finished coating is treated with protective compounds.

Advantages

- • Absolute imitation of the selected material.

• Relatively low cost.

Flaws

- • Plaque may appear over time.

• Additional treatment with impregnation every 1.5-2 years.

Wood or decking

Durability is determined by the choice of breed, the correct implementation of the supporting structure, installation and reliable protection of the material. The most suitable wood species are teak, oak, kumaru, bangkirai. They are hard, have high resistance to abrasion and the negative effects of the external environment. And also do not require treatment with impregnation.

Durability is determined by the choice of breed, the correct implementation of the supporting structure, installation and reliable protection of the material. The most suitable wood species are teak, oak, kumaru, bangkirai. They are hard, have high resistance to abrasion and the negative effects of the external environment. And also do not require treatment with impregnation.

Oil or marilka will emphasize the natural color. Sometimes spruce or pine is used, but it is worth considering the fact that these are soft rocks and over time scratches and dents appear on them, they lose their appearance and require additional care. To protect wood, it is better to choose impregnations based on natural oils and solvents.

Styling features

To cover the terrace, corrugated or smooth boards are used. Preferably, products with a drip. Board thickness 25-38 mm, length 2.5-5.5 m, width should not exceed 140 mm. Base slope 1.5-2%.

To cover the terrace, corrugated or smooth boards are used. Preferably, products with a drip. Board thickness 25-38 mm, length 2.5-5.5 m, width should not exceed 140 mm. Base slope 1.5-2%.

Logs with a section of 5 * 5 cm are laid on 2 layers of roofing material along the slope line, in increments of 30-60 cm. The boards are nailed at intervals of 8-15 mm, thus maintaining ventilation of the coating. The board is attached to the lags with self-tapping screws or on an adhesive base. Sometimes they use plastic logs, they are more practical.

Another option for wood flooring is the so-called garden parquet. The boards have a parquet lock that easily connects the modules to each other.

Advantages

- • Ease of installation.

• Levels the slope.

• Ideal ethical qualities.

• Optimum floor temperature is maintained even in the sun.

Flaws

- • Burns out quickly.

• Requires special, time-consuming care.

• The frequency of additional protective treatment depends on the degree of exploitation and the type of wood.

• Smooth boards become slippery after rain.

Wood-polymer composite

In appearance, it resembles a decking board, but DPS is made from a mixture of wood flour and plastic. The product is a hollow profile with internal stiffeners. The material is stable, non-slip and frost-resistant, so it is successfully laid on the terrace. Such a board has a thickness of 25 * 30 mm, a length of 2-6 m and a width of 10-15 cm. The warranty period is 10 years, practical 35-40 years.

Features of laying WPC

Special fasteners made of stainless steel are intended for laying DPS: rack frame, screws and clips. Wooden or metal slats are laid in increments of 35-40 cm. Terrace boards are laid across the frame. Steel clips enter the side grooves between the board, they fix the board on the frame and hold it. An expansion joint of 1-1.5 cm is left between the panels and the wall.

Special fasteners made of stainless steel are intended for laying DPS: rack frame, screws and clips. Wooden or metal slats are laid in increments of 35-40 cm. Terrace boards are laid across the frame. Steel clips enter the side grooves between the board, they fix the board on the frame and hold it. An expansion joint of 1-1.5 cm is left between the panels and the wall.

Advantages

• The coating does not require additional processing.

• Easy installation.

• Excellent appearance.

• Does not fade in the sun and maintains optimal temperature.

Disadvantages of WPC

• High price.

Read articles on related topics