How and from what wooden barrels are made. How to make a wooden barrel with your own hands? What tools are needed

Vegetables are salted in barrels, bulk products are stored, and water is kept in reserve. They are needed in the pantry, on the site, in the bath. How to make a wooden barrel with your own hands so that it is strong, reliable, durable, does not let water through and does not rot? What tools and skills are needed for the job, what will need to be studied and taken into account? This guide will help you master a useful craftsman and even start your own tub making business.

Wooden barrel for household needs

Cooperage - how to become a master

If the mood is resolute, there are skills in woodworking, and hands grow from where they should be, why not try to realize the idea of becoming a domestic cooper (cooper)? Bondar is a difficult craft that came from antiquity. Now there are very few masters of this business, and there are only a few high-class masters. Therefore, cooperage products are rare on the market, and if you can find them, then either the price or the quality does not please the buyer.

barrel assembly process

What tools are needed to assemble barrels

Having decided to make your first barrel, barrel or tub, you need to equip the workplace and stock up on the necessary tools, fixtures, and materials at hand. In addition to the usual carpentry kit, you will need to stock up on special cooperage equipment, fixtures and tools. This:

- carpenter's workbench, equipped for cooper's work;

- cooperage long jointer, circular humpback planer;

- a device for planing the edges of the boards from which the product is assembled);

- devices for tightening rivets (frame gate, chain tie, pole gate);

- plow, skobel, skobelka;

- hand-made patterns, templates;

- metal or wooden clamps for assembling the skeleton of the barrel;

- morning time (device for cutting the morning groove into which the bottom of the product is inserted);

- heels (metal, wooden, combined), tightness for a hoop;

- cooper's brace.

Fixtures and measuring tools

It should be borne in mind that coopers make a significant part of the devices and tools on their own, “for themselves”, ensuring that the handles of the tools are held in the palm of their hand, like a glove, and the machines and workbenches were tall.

On the left is a two-handed, on the right is a one-handed morning service and how to work with it

What you need to know for the manufacture of cooperage products

A distinctive feature of cooperage utensils is that they are assembled from specially prepared wooden planks called staves (in other words, frets). The shape and dimensions of the product are completely determined by the configuration of the planks, which are pre-made by the cooper. And the consumer qualities of wooden containers depend on the type of wood used.

Therefore, it is not enough for a cooper just to be able to master the tools perfectly. He must feel the "soul" of the tree and know the properties of each type of wood from which he plans to make this or that household item.

Staves are the main element for the manufacture of barrels

An experienced cooper will not make an oak barrel for storing honey - when stored in it, the honey will darken and acquire an unusual aroma. But oak barrels are indispensable for aging wine and other spirits: oak wood gives them new aromas and flavors.

The second element, without which cooperage products are inconceivable, is a hoop that holds the elements, tightens them tightly, so that wooden barrels do not leak. Hoops are made of metal and wood. There is an opinion that metal hoops are stronger, and the hassle with their manufacture is much less than with wooden ones. However, some masters think differently and make the most beautiful products using wooden hoops.

Tub on wooden hoops

Main details and manufacturing principle

One might get the impression that the task of becoming an amateur cooper is too difficult, and one can only quietly dream about how to make a barrel out of wood. But if you're serious about making your dream come true, it's time to roll up your sleeves.

First of all, you need to choose the type of product that will become your firstborn. With all their diversity, there are three types: with a conical, parabolic and cylindrical core. As already mentioned, the shape of a cooperage product is completely determined by the configuration of the staves from which it is assembled - the more complex the shape, the more difficult it is to make the treasured wooden barrel.

Influence of configuration on product type

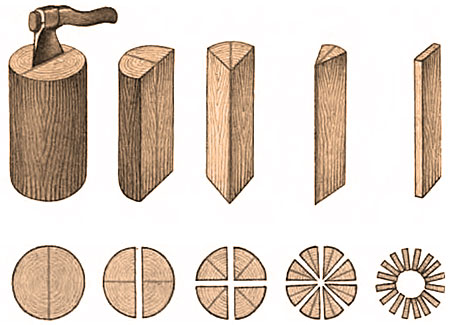

The figure above shows the types of cooperage utensils and the corresponding types of staves:

- Grooved, made in the form of a quadrilateral, the long sides of which have the form of parabolic curves. They are used in the manufacture of cooperage utensils with convex sides: barrels, barrels. Such staves are the most difficult to make, which predetermines the complexity of manufacturing barrels in general.

- The base of the tank is a cylinder. They are easy to manufacture, as they are rectangular grooved planks. It is easy to make such frets, but it is difficult to connect hoops with a constant diameter. When the wood dries out, the hoops no longer hold the rivets. Therefore, cylindrical cooperage products are practically not found.

- From straight grooved frets in the form of an elongated trapezoid, dishes are made, the skeleton of which is a truncated cone. When stuffing the hoop on a wide part of such containers, a very strong contraction of the rivets is achieved. This feature has found application in the manufacture of various tubs, tubs, jugs.

By the same principle, a mini-bath is built.

For the first experiment, it is desirable to choose the manufacture of a small tub, often called a barrel in everyday life.

How to make a garden tub for pickles

The barrel is the simplest cooper's product with a conical core. Having achieved success in the construction of the tub, it will be possible to try on how to make a more complex barrel at home. The creation process consists of three major steps:

- production of blanks (component parts) of the product;

- construction assembly;

- finishing.

Tub for beginners

Self-preparation of rivets for tubs

The reliability and durability of a wooden barrel depends on how carefully the staves are prepared. The most suitable are considered to be blanks, knocked out with an ax from logs and logs of sawn wood. Only the lower part of the trunks of old trees is suitable for this.

Oak wood, most often used for the manufacture of barrels, is very durable. But oak logs (blocks) are quite easily split with an ax in the radial direction. In general, the process of harvesting staves from different trees is approximately the same. There are single-row and double-row punching methods. A single row is suitable for splitting thin logs, a double row is suitable for massive decks.

Double row punching

The procedure for knocking out staves from the ridge:

- Split the ridge into 2 parts so that the split line passes exactly through its center.

- Each chopping block is also split in half - you get quadruplets.

- Split quarters into 2 parts, getting octagon. For a thin block of wood, the knockout process usually ends there. It is the eighth part that will serve as a rough blank for future riveting. This is a single row punch.

- If the ridge is thick, make a two-row punch: split each octagon in half along the annual ring (perpendicular to the core rays). The resulting logs are called gnatinniks.

- Split each gnathinnik in the radial direction. In this case, 1-2 riveting blanks will be obtained from a smaller gnathin and 2-5 blanks from a larger one.

- Perform a small processing of the blanks: chop off the wedge-shaped protrusions from the side of the core and sapwood (weak young wood from the side of the bark).

- Send blanks to dry. In the summer they need at least 3 months to dry in the open air or resort to artificial drying.

The sequence of making rivets

Making rivets from blanks

Prior to the manufacture of rivets, it is necessary to make templates and patterns in accordance with the shape and dimensions of a particular product.

To make staves for tubs or barrels, you need:

- Make markup.

- Perform roughing of each riveted blank: slightly round the outer surface, and mow the edges with an ax.

- Start finishing the outer surface with a straight plow or planer, controlling the process with a template.

- Plane the inside side with a fillet or a humpbacked staple.

- Use an ax to cut the narrow edges of the frets, controlling the accuracy with a template.

- Align the surface of the edges with a jointer.

To determine the required number of rivets, you need to find the largest perimeter of the tub: multiply the diameter by 3.14. This value will be equal to the sum of the widths of all elements. For simplicity, in order not to measure the width of each part (and it can vary), you can set aside a straight line segment on a flat surface equal to the largest perimeter of the barrel. Lay finished rivets across the line until it closes.

Sheet metal hoop

Production of metal hoops for the tub

The cooper has to deal with both wood and metal, because the hoops that tighten the dishes have to be made independently from a metal sheet. But it is easier to make hoops from hot-rolled steel tape. For this you need:

- Determine the perimeter of the tub at the location of the hoop, add to it the double width of the strip.

- Using a hammer, bend the strip into a ring, overlapping the ends of the strip. Drill or punch 2 holes with a diameter of 4-5 mm, install steel rivets.

- From the inside, flare one edge of the hoop with hammer blows.

Skeleton Assembly Steps

To make a small barrel at home, two hoops are enough, corresponding to the perimeters of its upper and lower parts.

Stages of assembling the skeleton of the tub

Rivets-sidewalls, pulled together by hoops, form the skeleton of a barrel made of wood. The skeleton should be assembled like this:

- Attach 3 supporting rivets to the small hoop with clamps at approximately the same distance from each other, which will allow you to install the structure vertically.

- Alternately inserting frets, fill in the sector between the two supporting rivets, fill in the space around the entire perimeter of the small hoop.

- Using a hammer and a heel, upset the small hoop so that the parts are securely closed.

- Put the lower hoop on the skeleton and also besiege with a heel.

- File the ends of the skeleton along the line drawn by the thickness gauge.

- Remove the irregularities inside the skeleton with a stapler.

- Plane the ends with a humpback planer.

- With a straight plow, chamfer inside the core from the ends. This will prevent them from chipping and make it easier to insert the bottom.

- Using a chime, cut a groove (chime) where the bottom will be inserted.

Cleaning irregularities with a bracket

Assembly and installation of the bottom of the tub

The fewer joints in the bottom, the higher its reliability. Therefore, for the bottom you need to choose the widest and thickest blanks. The procedure for making the bottom of a wooden barrel with your own hands is as follows:

- Cut off the edges of the boards, temporarily rally them on a workbench.

- To determine the radius of the bottom, put the legs of the compass in the groove-chime. Using the sampling method, select a compass solution that divides the perimeter of the chime into 6 equal parts.

- On cohesive rivets, draw a circle with the resulting compass solution.

- Within the circle, make marks at the places where the studs are to be installed.

- Release boards. Drill holes in the edges in the marked places and drive in wooden or metal studs.

- Tightly join the boards on the studs.

- Plane the bottom on both sides.

- From the center again draw a circle of the same radius as before.

- Cut out the bottom with a circular saw, leaving a small margin outside the circle.

- With a straight plow, chamfer on both sides so that the thickness of the wood at a distance from the edge equal to the depth of the chime remains equal to its width.

- Knock down a large hoop with a heel, loosening the fastening of the rivets. Insert the bottom into the chime.

- Carefully turn the tub upside down, upset a large hoop.

Now the homemade tub is almost ready. It remains to make a lid and a circle. It will not be difficult - you can focus on the manufacture of the bottom. After checking the barrel for leaks, you can start cooking pickles in it.

You may also find it helpful to watch the tutorial video.

Video: How to make a wooden tub

Using the techniques described, you can make tubs for indoor plants or flower beds for landscape design.

Potted flower beds will decorate the garden landscape

How to make a reliable wine barrel

Having mastered the manufacture of tubs, you can proceed to the construction of a wooden barrel for aging wine with your own hands. And if homemade wine is not the subject of your interests, then the acquired skills can become the basis of a profitable business. After all, the demand and prices for cooperage products on the market are quite high.

The choice of material and the manufacture of rivets

The material for the body of wine barrels is exclusively oak wood. Rivets for them are prepared in the same way as for tubs, that is, split rivets are used. For the experiment, you can make a wooden barrel from boards (oak, of course). In this case, the barrel will last less than the one made of chipped frets. It should be borne in mind that boards for riveting blanks should only be straight-layered, otherwise the walls will crack.

Selection of boards for riveting blanks: a) such boards are unsuitable; b) these boards will fit

The frets for the barrel have a complex configuration. Each of them is thinner in the middle than at the ends, the outer surface is convex, the inner grooved. And the side edges look like gentle parabolas. Accordingly, it is more difficult to make barrel frets than barrel frets.

Steps for making barrel frets

First of all, you need to make a template, a pattern. Stages of making staves for a barrel:

- Rough extrusion with an ax with a semicircular blade to give it the shape of a prism. Reducing the thickness of the middle part by 15-20%.

- Beveling the side edges with an ax. Rounding of the outer face (control with a template). Measuring the width of the riveting in the middle with a template, determining its dimensions at the ends, drawing marks.

- Beveling the workpiece to the ends along a slightly curved arc. Chamfering on the side edges with pattern checking.

- Planing the outer plate with a planer or straight scraper.

- Treatment of the inner surface with a humpback planer or a humpback scraper.

- Edge jointing.

Assembling a wooden barrel

The beginning of the assembly does not differ from the assembly of the tub

Stages of assembling a wooden barrel

The beginning of the assembly does not differ from that for the tub until the moment when all the rivets are inserted into the upper (the barrel has 2 bottoms!) Hoop. Next, you need to do the following:

- Stuff the second hoop, called the neck hoop.

- The lower part of the unraveled core is steamed to increase flexibility.

- Steaming time depends on the hardness of the wood and the size of the cross section of the frets. When constructing a thin-walled barrel with a slight steepness of the sides, steaming is not required.

- Pull off the steamed rivets with a chain tie or a cooperage collar, put on the upper hoop, then fill the neck and middle hoops.

- Harden and dry the core in an accessible way, for example, gently rolling the core, in which a layer of burning chips is embedded. You can use a gas burner, a blowtorch. The main thing is that the wood, as it were, “tanned”, but not charred. This procedure fixes the shape of the barrel, and the taste of drinks from it only improves.

- Perform the same operations as with the skeleton of the tub: trimming, cleaning surfaces, cutting chimes.

- Make and insert the bottoms by performing the same operations that were performed for this purpose for the tub. Only when installing the bottoms, in addition to removing the top, you also need to loosen the neck. In the upper bottom, pre-drill a hole for the bay, make a cork for it.

Tempering (firing) wooden barrels

You can get acquainted with the process of making wine barrels visually by watching a short video.

Video: How to make a wooden barrel

Video: Barrel for wine from boards

The construction of a barrel for a bath is similar

You have received some information on how to make a wooden barrel and tub with your own hands. If you have any questions, please consult an expert.

A wooden barrel is the best container for storing wine and various pickles, because wood is an environmentally friendly material that preserves the taste and usefulness of products. This indispensable item in the household can be purchased ready-made, but if you have free time and desire, then using our tips, making a barrel with your own hands will not be difficult.

Masters involved in the manufacture of barrels are called coopers, and the process of creating containers is called cooperage. This is a kind of art that originated in ancient Greece, but, oddly enough, the technology has changed little since then, and wooden packaging is still popular, especially among winemakers. Today we invite you to get acquainted with the basics and some of the subtleties of this craft.

Choice of wood

The first responsible task is to choose the right type of wood for the manufacture of containers. Consider the main varieties used, as well as their pros and cons.

First on our list is oak. It is rightfully considered the most suitable, so to speak, classical material used in cooperage. Its wood is strong, flexible and saturated with special tannins that act as an antiseptic. It is noteworthy that under the influence of moisture, oak barrels only become stronger over the years, so their service life is quite long. Another feature of oak is a pleasant aroma with hints of vanilla, which it gives to the substances stored in the barrel.

Oak is the best material for barrels

Spruce and pine can also be used to make barrels. These are soft woods that are easy to cut and process, but their strength indicators are average. The main disadvantage of such wood is the characteristic resinous smell, due to which it is not often used to create food containers.

Of the conifers, cedar is also popular in cooperage, although it is more widely used in those parts where its plantations are extensive. According to its characteristics, it is similar to pine and spruce, but there is practically no foreign smell from cedar barrels. Containers made of this material are suitable for storing food; it is believed that it is especially good to store dairy products in them.

Another material from which you can make a barrel is linden wood. It belongs to the fibrous varieties of wood and, due to its structure, lends itself well to cutting, chiselling and processing. The material is durable, practically does not dry out and has no smell, so barrels made from it have won recognition as one of the best for transporting and storing honey, caviar, pickles and other delicacies.

A budget but durable option is aspen. This tree is durable, resistant to moisture and has antiseptic properties. Aspen barrels are ideal for storing various pickles. A feature of aspen is a tendency to strong swelling, but in cooperage this is rather an advantage, since it allows you to achieve a very tight closure of the rivets.

Making staves

The next thing to do after you have decided on the type of wood is the manufacture of barrel parts. You should start with rivets. They are tapered at the edges or rectangular boards that can be chipped or sawn. The former are more durable, since the structure of the fibers is not destroyed when splitting a solid wood.

Barrel parameters according to their volume

Barrel parameters according to their volume In order not to be mistaken with the number of staves, you must immediately determine the size of the barrel. After that, you will need to make a life-size pattern for the riveting and the bottom. Then a simple calculation should be carried out. The required amount can be determined using the formula: 2 * Pi * R / W, in which "Pi" is a constant value; R is the radius of the bottom of a barrel with smooth sides or the middle of a container with convex sides; W - riveting width.

Making a barrel with your own hands from chipped staves is a laborious process and requires certain skills. The main task is to split the workpiece into even fragments and at the same time get as little waste as possible.

The split can be carried out in the radial and tangential directions. In the first case, the split plane passes through the core of the deck (this method requires less effort), and in the second it does not touch it. When working with hardwood, the second method is not recommended, as it complicates and slows down the process.

The scheme of splitting the deck into rivets

The scheme of splitting the deck into rivets Raw material is most easily processed, it is optimal if the tree for making the barrel is freshly cut. However, not everyone has the opportunity to purchase such wood, and as an alternative, you can look for suitable blanks among the firewood that is on sale for furnaces. In urban conditions, sawn poplars can become a material. These trees often lie in the yards for a long time after they have been cut down, waiting for their removal to the landfill. In the absence of other options, you can use the boards. When choosing them, pay attention to the fact that the annual rings go along the plane of the board and are not sawn.

The shape of the rivets depending on the type of barrel

The shape of the rivets depending on the type of barrel Having pricked a sufficient number of rivets, they are left to dry. In the summer, you can lay out the material under a canopy and leave to ventilate, this process will take about 3 months. If there is no possibility or desire to wait, use another method. For artificial drying, paper is glued to the ends of the blanks with carpentry glue and the riveting is placed for a day in the oven of a well-heated Russian stove. After this procedure, the material will be suitable for further processing.

Making a hoop

Another important component of the barrel, which allows you to collect all the rivets into a single whole - hoops. According to the material of manufacture, they can be metal and wood. Iron has more strength, but it also has a drawback - a tendency to rust, which over time significantly worsens the appearance of the product. Therefore, metal hoops are used only if increased strength is required.

Usually a modern wooden barrel, purchased or made with your own hands, has 4 hoops. Those that are closer to the center are called farts, and the extreme ones are called mornings, if the barrel has a significant volume, there can also be additional cervical ones between them.

Hoops with tie-lock

Hoops with tie-lock The thickness and width of the hoops are directly related to the volume of the container. If its volume does not exceed 25 liters, then they have a thickness of 1.6 mm and a width of about 3 cm, for a 50-liter width it increases to 3.6 cm, and for a 100-liter to 4-4.5 cm. If the barrel holds 120 liters or more, then the hoops for it should have a thickness of 1.8 mm and a width of 5 cm.

Even if you use wooden rims for the barrel, you will also need the ability to make them out of metal, since the assembly cannot do without the so-called working metal hoops. To assemble a barrel of these hoops, you will need four. In terms of structure and characteristics, they are identical to permanent ones, and are made as follows:

- Strips of the desired size are cut from sheet steel. As a cutting tool, you can use locksmith or chair scissors.

- Holes are made at both ends of each strip with a punch and fastened with rivets.

- To make the hoop easier to put on, one of its edges is forged.

In working hoops, instead of rivets, the use of bolts is allowed, and if the capacity of the barrel is small, then steel rims can be replaced with wire ones. The diameter of the wire in this case should be 4-5 mm. For those who do not want to mess around for a long time, making hoops on their own, ready-made designs with a tie-lock are on sale.

Barrel assembly

Considering how to make a barrel with our own hands, we came to the next stage - assembling the skeleton of the container. It consists of rivets tied with hoops (at first temporary).

The assembly of the barrel begins with a smaller hoop. Inside it is inserted at regular intervals and fixed with clamps 3 support rivets. Further, other rivets are added between the two supporting ones until the entire space is filled. Then the hoop is upset using a hammer and a wooden block with a flat end so that all the fragments close together more tightly. After that, a larger hoop is put on the rivets and also upset.

Assembly of the skeleton

Assembly of the skeleton Before putting on the rims on the bottom of the barrel, it is recommended to immerse the material in boiling water for half an hour. To carry out further work, you will need 1-2 assistants. After steaming, the barrel is placed on a flat surface, the remaining free end of the rivets is wrapped with a rope, the ends of which are tied to some firmly fixed object.

Further, a crowbar is inserted between the stretched parts of the rope and scrolled so that they are intertwined with each other. At this time, your assistants should keep the barrel in place. When it is possible to achieve the desired bend and seal of the rivets, the remaining hoops are put on and fixed. The finished structure should be trimmed and hardened by treating with a burner or blowtorch.

Manufacturing and installation of bottoms

Bottom manufacturing

Bottom manufacturing As a bottom for a barrel, it is better to use a single piece of wood or wide and durable planks (it is desirable that the number of joints between them is minimal). Selected boards should be planed so that they can be overlapped and then stapled together. From the resulting workpiece, cut out 2 circles of the required diameter and sharpen their edges until small bevels form.

To fix the bottom, you will first need to loosen the tension of the hoops at the bottom of the barrel, slightly pulling them up. Then the bottom is placed inside and the hoops are upset in place. If the top of the barrel is not removable, then the procedure is repeated for the second side, not forgetting to pre-drill the filling hole. After making sure that the bottom is tightly connected to the frame, the working hoops are replaced with permanent ones, and the container is ready.

Soak

Now you know how to make a barrel yourself, but there is one more important nuance - putting your product into operation. Before use, the barrel needs to be processed, otherwise the products stored in it may acquire an unpleasant aftertaste or even deteriorate.

To begin with, the container must be thoroughly rinsed to get rid of sawdust, small debris and excess tannins. Rinsing is continued until foreign odors disappear and the water becomes clear.

Before use, the barrel must be prepared

Before use, the barrel must be prepared Next, the barrel is steamed to disinfect it and improve the sealing of the staves. To do this, the container is filled with boiling water by about a third and scrolled so that the water "walks" over the entire surface of the walls from the inside. Then the water is left inside until it cools, drained and the process is repeated again.

After steaming, the barrel should be soaked. Usually this procedure takes about a month, and every two days the water in the tank needs to be updated. In the first days of soaking, there may be leaks in the product, this is a variant of the norm, but the flowing water needs to be replenished.

Before laying the products, the container must be doused with boiling water from the inside. This will protect the wood from absorbing odors and allow it to be used for different foods without mixing its flavors.

A container treated with boiling water before laying food will last longer

A container treated with boiling water before laying food will last longer Summing up, we can say that a do-it-yourself barrel is an excellent solution for storing homemade pickles, as well as for wines and other alcoholic beverages. By making such a container yourself, you will not only save money, but you can also be completely sure of the quality of the product, and, consequently, of observing the proper conditions for storing your products.

How to make a wooden barrel with your own hands, drawings and a detailed description of the manufacture.

The figure shows a barrel in a section:

1.

Lid.

2.

Small hoop.

3.

Boards (riveting).

4.

Big hoop.

5.

Bottom.

The manufacturing process of the product in question can be divided into several stages.

MATERIAL SELECTION

The most common material is oak. It is good to withstand alcohol in oak barrels and prepare pickles for the winter. You can also use cherry, mulberry, linden, aspen or ash.

DESIGN CALCULATION

Any design is determined by the following dimensions:

Height (H) - 600 (mm)

small diameter (d) - 420 (mm)

large diameter (D) - 465 (mm)

number of staves (n) - 20

the angle of inclination of the side faces to the center of a regular polyhedron (φ) - 360/20/2 = 9°

By geometric constructions, we obtain the dimensions of the riveting.

Reference:

To greatly facilitate assembly, it is desirable to make the rivets at the top and bottom thicker than in the center by 1/5. If the thickness of the riveting in the center is 10 (mm), then at the edges it will be 10 + 10/5 = 12 (mm).

MATERIAL PREPARATION

The lower part of the trunk sawn into chocks is well suited for blanks. Chocks of the desired length must be split into boards in the direction of the fibers. Send the prepared boards for drying in a ventilated room for a period of two months.

Reference:

In order for the boards to be well blown, it is better to fold them in a checkerboard pattern.

MANUFACTURE OF HOOPS

Hoops can be made from a hot-rolled tool strip 3 x 30 (mm). Ideal if the strip is bent to, but you can also manually. We drill two holes and connect the ends of the hoop with rivets, as shown in the figure.

BOTTOM ASSEMBLY

We will assemble the bottom from boards and planks. In the boards, we mill grooves along the entire length of the end surface. Insert the planks into the grooves, and press the boards against each other.

From the resulting shield, cut out the bottom of the estimated diameter.

We grind the end surface at a slight angle.

How to make a wooden barrel with your own hands, the drawings are at hand, all the details are made, you can start assembling the product:

1.

We collect rivets around the perimeter of the small hoop, using small homemade clamps.

2.

After inserting the last stave, move the hoop as far as possible to the center of the barrel length.

3.

Warm up the lower rivets in hot water for 15…20 (min.).

4.

Install the prepared structure inside a large hoop, preferably on a flat surface.

5.

We tighten the structure with twine and move the large ring to the center of the barrel.

6.

We continue to tighten the structure with twine, after the rivets are completely pulled together, we put a small hoop on top of them.

7.

The skeleton is assembled and it must be burned from the inside, using any of the proposed methods: gas burner; blowtorch; small fire.

8.

Align the edges of the barrel.

9.

Loosen the lower metal ring, insert the bottom into the grooves of the rivets, and push the small metal hoop back to its original position.

10.

Do the same for the cover.

11.

Check the product for leaks, if necessary, seal the cracks with barrel grass.

12.

Sand the outer surface of the product and cover it with a thin layer of beeswax.

13.

If the barrel is made of oak, it must be washed with water until the drained liquid becomes clear. This procedure can take up to two weeks.

As you can see, it is quite possible to make a wooden barrel with your own hands.

Share with friends!

You can buy almost everything today. But it’s quite difficult to find a wooden barrel, really high-quality, solid, and besides, it is expensive. There is another point that not everyone takes into account - it is not a fact that a finished barrel is suitable for a specific purpose. The reason is the mismatch of the wood species. The conclusion is unequivocal - to make a barrel yourself. And if you deal in detail with the drawings, the nuances of the work, then it will not turn out to be any complicated and impossible with your own hands.

Pine

- Elasticity, bending flexibility.

- Easily processed with household tools.

- When the temperature rises, it will resin abundantly.

- The characteristic smell that will always be present inside the barrel.

Juniper

Strength combined with ease of processing.

Big weight.

Recommendation - it is advisable to use for the manufacture of relatively small barrels for transportation (storage) of bulk materials.

Oak

- It bends beautifully after the tree is well steamed.

- Contains fungicides that protect the structural elements of the barrel from decay.

High material cost. To make a high-quality barrel, you will have to use a tree that is at least 80-100 years old.

Recommendation - if the barrel is intended for storage (sourdough) of products, aging of wines, and so on, then oak boards should be chosen.According to the reviews of those who have already made a wooden barrel with their own hands, you can also use such types of wood as linden, ash, aspen, mulberry.

The choice of material is a rather specific issue. If a barrel is needed to store stocks of wine (cognac, vodka), sourdough (salting) of cucumbers, watermelons, apples, and so on, then the best tree for it is oak. This is undeniable. But it is hardly correct to spend such wood (given its cost) on making a container with your own hands, in which it is supposed to store cement, sand, bulk products. Other breeds, “simpler”, are quite suitable for these purposes.

The procedure for calculating the parameters of the barrel

Based on its purpose and installation location, dimensions and design features are selected. In everyday life there is some confusion with the concepts. In principle, both the tub and the barrel are containers of a certain capacity, which are assembled manually from separate boards (staves, fret in the language of professionals). The difference is only in the geometry. The pictures explain everything well.

What is defined for the drawing:

- Barrel height

- Diameters (large and small).

- The angle of the staves and their number.

To simplify calculations, it is advisable to focus on typical data that are used by specialists when drawing up barrel drawings.

Do-it-yourself wooden barrel - instructions

The algorithm of actions is clear from the figures, which show the main stages of work.

But separate explanations will not be superfluous.

Rivets can be made from logs or boards. The first option is preferable, although its implementation by hand is much more difficult. The fact is that only the lower part of the tree trunk goes to the manufacture of the barrel, from the roots to the branches. You will have to chop logs (decks) on your own.

What is the feature?

- The ax blade must hit exactly in the center, along the diametral line. This will somewhat facilitate the work and allow you to get high-quality rivets in larger quantities (based on each deck).

- Boards are obtained by splitting, hewing chocks. Wood processing is always carried out along the fibers, and not across.

To facilitate bending, the rivets are given an irregular geometry. The thickness at the ends of each board should exceed the same parameter in the center by about 0.2. That is, if it is supposed to assemble a barrel from 10 mm boards with your own hands, then they are hewn with the expectation that their thickness in the lower and upper parts of the container is at least 12.

Drying staves

Various sources indicate terms that are measured in months, or even years (up to 3). At this point, it is necessary to focus on local conditions, the initial and its porosity. Recommendations for artificially accelerating this process when doing do-it-yourself work are not entirely useful. Without practice, it is difficult to determine the optimal mode for the same electric / cabinet and the exposure time of the tree in it. Experienced craftsmen advise to wait until the moisture evaporates from the wood naturally.

It is only necessary to place it in a room with proper conditions - a temperature of at least +20 ºС and good ventilation. You may have to wait 2 or 3 years. But a high-quality barrel "in one day" is not made, and this must be understood.

If we are talking about a container for household purposes, then you can dry the staves even on the stove. But in any case, a barrel is not assembled from raw boards. After a couple of weeks (due to shrinkage of the wood), gaps will begin to appear between them. Checked.

hoops

Finding metal strips, drilling holes for rivets with your own hands is easy. The only thing you should pay attention to is that it is better to take tool steel. It is characterized by increased strength (tensile strength) and corrosion resistance. If it is pre-treated with drying oil and then burned (for example, with a blowtorch), you will get hoops of the original light brown shade.

Bottom

It is cut out of a shield, which is assembled by hand from pre-prepared boards. Moreover, using a different technology than frets (sidewalls). Their thickness does not change along the length. To ensure the tightness of the joints, the ends are milled, that is, the assembly is carried out according to the well-known tenon-groove principle. In some cases, special (sealing) rails are installed.

Barrel assembly

The sequence of actions is shown in this figure.

This work is not done alone; 2 - 3 assistants will definitely be needed. Rivets are placed along the lower hoop with maximum fit. If the last board does not "fit in", it should be trimmed slightly to size. This is where spares come in handy, since the first or even the second time, with your own hands, without experience, it may not be possible to adjust the “finishing” board. A little bust with a sample of wood, and it will have to be rejected.

The penultimate stage - installation of the bottom

And only after that, the hoops are coupled (if they are adjustable) or their final landing in place (in height).

The last step is wood sanding.

How to process the barrel from the outside is decided on the spot (“skin” and manually, sanding / machine), but after that it is desirable to cover the container with beeswax (thin layer). This will provide additional protection for the tree from external factors.

Good luck, beginner coopers!

Cooperage is one of the most difficult craft, so the answer to the question, how to make a barrel with your own hands, will also be difficult. This is a very time-consuming process, requiring a decent professional level from the performer and the availability of a large number of tools for wood processing.

Types of barrels for their intended purpose and wood for their manufacture

Before you wonder how to make a barrel you need to decide what you need it for. The choice of material and method of manufacture depends on this. This type of container is made for the following purposes:

- for fermentation, aging and storage of spirits, wine and beer;

- for the preparation and storage of pickles;

- for storage of dry products;

- for storing honey, etc.

Barrels for drinks have two bottoms and a hole for inserting taps. The same type of container, but without holes, was previously used for long-term storage of certain products (for example, corned beef).

For other purposes, barrels with one bottom are enough - they are also called tubs. From above they are covered with a lid or circle for oppression. Making these parts is much easier than the bottom. Make a wooden barrel can be from such types of wood as:

- oak;

- ash;

- cherry;

- Linden;

- alder and others.

The wood of the first three types is the most versatile. It is equally suitable for containers of any purpose. However, the "champion" should be recognized as an oak barrel, which, being strong, reliable and durable, provides ideal conditions for storing food.

Oak products have antiseptic properties, release tannins into alcoholic beverages, improving their taste, and also easily withstand the effects of brines when harvesting pickles. Ash and cherry are the first "deputies" of oak wood. They have similar but weaker properties. Therefore, we will consider . The manufacture of containers from other types of wood, such as linden, has no fundamental differences, with the exception of the nuances of the finish.

Oak barrel for honey

Oak barrel for honey Rules for the procurement of material for barrels

Before you start doing handmade wooden barrel, you should prepare and prepare high-quality material. The wood must be mature, healthy, free from defects (knots, slant)

The best time for harvesting material is late autumn or winter, when the natural moisture content of wood is at a minimum.

It is unlikely that you will be able to meet all the requirements. For example, for the manufacture of staves for wine and cognac barrels of the highest quality category, the process of drying and aging wood takes 6–8 years, but if you are only concerned about how to make a barrel for yourself, follow these rules:

- Before drying, the logs are split into blanks of the desired thickness;

- drying is carried out in a place closed from direct sunlight - under a canopy, in a barn, etc .;

- The duration of drying depends on many factors and can take 1-3 months;

- the residual moisture content of the wood before processing should be about 25%.

Speeding up the drying process using hot air and other methods usually results in deterioration of the quality of the wood and its properties in the finished product. Tips, , also take into account the need to hold the processed rivets before assembling the product. As a result, the residual moisture content of the wood should be 17–20%.

Making rivets and tools for this

For those who wish make your own oak barrel the most difficult will be the manufacture of rivets. The process of marking and splitting logs is clearly shown in the following figure.

As a result, you will get blanks of a conical section, from which, after drying, riveting is made. This detail has a complex shape, so its manufacture places high demands on the skill of the performer. The main dimensions of the barrel and its elements, depending on the volume, are as follows:

This table will help you figure out how to make a barrel, and the drawing - to understand how to give the rivets the desired shape

Tool

Tool And what tools do you need for this. The curvature of the sides should provide the barrel with a taper of about 8°, due to which the product is resistant to loads from the outside and from the inside. To treat the surfaces of rivets, a planer, jointer, sherhebel, plow and other tools of this group are used. In this case, the outer surface of the part should have a slightly convex shape, and the inner one should have a concave shape.

|

Barrel capacity, l |

Height, mm |

Center diameter, mm |

Edge diameter, mm |

Riveting width, mm |

Riveting thickness, mm |

Bottom thickness, mm |

Planing accuracy and quality are regularly checked against the template. To calculate the number of rivets, the largest circumference (in the center of the barrel) should be divided by the width of the blanks. This way you will also determine the exact and uniform size of the part. The process of making rivets can be seen in the video.

After that, the answer to the question of how to make an oak barrel with your own hands, will become clearer as you master the toughest challenge.

Making bottom shields and tools for this

For the manufacture of bottom shields, 4–6 planks are used, interconnected by studs made of wood or stainless steel. Drawings, or, more precisely, instructions, of this process are given here

But at first we will limit ourselves only to connecting the planks, since the rest of the operations are carried out taking into account the dimensions of the assembled barrel body. We will have to do the following:

- draw a circle on the shield: its diameter should correspond to the size of the bottom of the barrel, to which is added twice the depth of the morning groove (this is 6 mm);

- perform filing along the contour with a bow saw or circular saw;

- chamfer around the entire circumference so that the bottom enters the morning groove.

In a similar way (adjusted for a larger or smaller diameter), a cover and a circle for oppression are made. If you intend make your own barrel for drinks that have two bottoms, it should be remembered that such products are made according to individual measurements for the top and bottom. You will see the result of your efforts only after you collect all the details into a single whole. Assembling the barrel is the most enjoyable stage of its manufacture. We will describe how this process is carried out below.

Barrel Assembly Order

The following information about how to make a barrel, will be recommendations for its assembly. For this, in addition to wooden parts, you will need metal hoops - assembly and permanent. The first of them serves to set and fix the complete skeleton. Permanent hoops are divided into morning and cervical (umbilical). They provide tightening of the rivets. To make a wooden barrel from the available kit of parts, you will need to perform the following operations:

- using clamps on the assembly hoop, fix two, and preferably three, rivets;

- Fill the space between them with the remaining parts;

- put on a neck hoop from the fixed side;

- Steam the loose side of the skeleton and pull off the rivets with the help of a collar (noose), after which put on the morning and neck hoop on this side of the skeleton;

- on the side of the assembly hoop, cut a morning groove for installing the bottom;

- cut and process the first bottom, then put it in place;

- On the same side, install a morning hoop, which finally fixes the bottom;

- to finish the inner and outer surface of the barrel body;

- to carry out hardening (firing) from the inside;

- Repeat the bottom installation operation on the opposite side.

The initial stage of assembly can be seen in the video

.

One more video

will give an idea of the subsequent operations. However, in this case, an allowance should be made for the fact that professionals work here, who have their own techniques and perform many actions automatically. Perhaps not everything will work out the first time, but how to make your own oak barrel you will definitely learn.

For barrels with a capacity of up to 50 liters, four hoops are used; for larger containers, their number is increased to six. They are made from a steel strip 30–50 wide and 1.5–2 mm thick. The diameter of the hoop is determined by measuring the place of its installation on the body of the product. Double the bandwidth is added to the value obtained. This is necessary to connect the strip into a ring using rivets made of forged steel wire with a cross section of 4–5 mm.

Answering the question how to make a barrel, it is necessary to mention that one edge inside the hoop requires flaring. This gives it the necessary taper for a snug fit to the frame rivets when putting on and upsetting. Cutting the morning groove is performed using a special tool, which is called a morning time in professional slang. The procedure is somewhat reminiscent of opening a round tin can.

In an article about how to make a barrel, it is impossible not to mention the hardening of the product. Most often this is achieved by firing. This ensures increased resistance of wood to moisture, organic acids and other influences. It is most convenient to perform the firing of a case without a bottom using a burner such as a portable forge

Finishing surfaces, drilling holes for taps (chops) is done before firing.

Checking the barrel and preparing it for use

Our advice on how to make a wooden barrel with your own hands, completes with information on how to check its tightness and prepare the product for use. To search for leaks, the barrel is filled with water. If within an hour of filling it is still leaking, you will need to take steps to seal it. To do this, there is a proven "old-fashioned" method using cattail, which is also called barrel grass. They caulk leaks. Another method of sealing is waxing with natural wax.

Each master has his own answers to the question, how to make a barrel, and many professional secrets, for the disclosure of which one would have to write an entire monograph. Therefore, you will have to turn to experts more than once for help on a variety of nuances of the barrel manufacturing process. By the way, the literary hero Robinson Crusoe was never able to cope with this task. When you achieve the tightness of the product, it remains only to prepare the barrel for use.

Answering the question how to make an oak barrel, should also give recommendations for soaking it. Most often this is done with plain water. The procedure takes up to 10 days with fluid changes every two to three days. However, for barrels intended for strong drinks, soaking lasts from one month to six months using alcohol-containing liquids with a strength of 18-55%. In this article, we have tried to answer the main questions regarding how to make a barrel. We hope that this information will be useful to you.