How to lay paving stones? Paving stone laying: technology, prices

There are several options for finishing the adjoining territory of modern buildings. The most common of these is the laying of paving stones. The wide use of the material is associated with the variety of its types, colors, shapes.

Advantages of pavers

The main advantages of the material include:

- low cost, ease of care;

- high quality;

- durability (the period of operation is up to 30 years);

- resistance to environmental influences;

- environmental friendliness - paving stones do not heat up under the influence of the sun and do not emit harmful substances;

- aesthetics - the material has many shades that do not fade in the sun.

Where applicable

Paving stones are used for paving garden paths, recreation areas, places near the pool, entrances to the garage. Also, the material is laid around any summer cottages: gazebos, baths, terraces and other buildings. They make borders for flower beds from paving stones, pave it around garden sculptures. If you intend to ennoble the adjacent area with this material on your own, then before laying the paving stones, you need to familiarize yourself with the technology of its paving, without which the result of the work may turn out to be unsatisfactory.

Laying methods

There are several basic styling methods. Each of them depends on the purpose of the future coverage: it will be a parking lot, a blind area or ordinary pavement paths. Directly during laying, the site owner decides on the need to use a curb fence, since it is not mandatory.

Project: creation and components

The first stage of preparatory work is the development of a project, which includes the coverage area for paving and the expected loads, slopes and drainage system, type of tile and method of its installation.

Its development is started after geodetic and control and measuring works, during which the "separation" of the site is carried out. After that, control points are determined on it and wooden or metal pegs are hammered. Special marks are made on them, according to which they are later guided during the installation of paving stones. With the help of a thread or a thin rope stretched between the marks, the boundaries of the coating are established.

Preparatory work

We continue to study the question of how to lay paving stones. It is important to prepare a dense and stable base. To do this, remove the top layer of soil. The thickness is calculated depending on the type of material itself. On average, 25-65 cm of the top layer of the earth is removed. If the soil at the bottom of the pit is unstable, it must be cleaned of tree roots, plant remains and additionally compacted.

If under the removed layer there are low-permeable layers of soil (humous chernozem, plastic clay), then the excavation is increased until stable soils are found.

If this entails a significant increase in the pit, then the excess soil removed is compensated with crushed stone or any soil with suitable qualities. Laying paving stones is impossible without determining the depth of groundwater. If they are located above the level of the future base, it is reduced through drainage work. In small areas, it is not difficult to perform such work, but in large areas they use special equipment: bulldozers, scrapers, etc.

Site profiling

This stage often combines surface design (intersection, corners and roundings) taking into account the level of surfaces and slopes. It is important to take into account the landscape and natural features of the object.

The calculation of the slope of the surface is carried out depending on the sewer pipes. It is recommended to do it in the range of 2.5-4%, which corresponds to a slope of 2.5-4 cm / m in length. The primer layer is leveled with coarse-grained sand with a layer of up to 1 cm. Next, the leveled bottom of the pit is vibrocompacted. The leveling of the surface and its ramming must be taken with all responsibility, as they play a serious role in the formation of drainage and the stability of the future surface.

Surface framing

Before laying the paving stones, the boundaries of the pit are calculated and fixed with curbs or curbs, between which the paving stones will be located. They reinforce the edges of the paved surface while maintaining its shape. The base for the curbs is semi-dry concrete. The gaps between the elements are about 3 mm. They don't fill up.

Paving stone laying: base preparation technology

The formation of the correct base over a flat, compacted soil is the key to successful and high-quality laying of paving stones. When it does not meet the requirements of the project, the pavement may not withstand the load and in the near future cease to fulfill its functions. As a material for the base, gravel or crushed stone of a fraction from 5 to 40 mm is used. It is laid in a layer of 10-15 cm thick. After that, it is compacted (it is reduced by 20% of the original thickness) to give strength and reliability during operation.

As a material for the top layer of the base, it is desirable to use crushed stone of the middle fraction between the granular base and the bedding. This will make it possible to avoid mixing the bedding with the lower layers and to exclude subsidence of paving stones and the movement of joints during its operation.

The thickness of the base should be calculated based on the intended purpose of the surface and the expected loads on it. Granite paving stones, used for paving the local area, paths and sidewalks, require a base 20 cm thick. If the surface is subjected to constant heavy loads (during the movement of cars), then it must be increased to 30-50 cm. Strength is also affected by soil properties, for example, clay requires a thick base.

Underlayment

On top of the compacted carrier layer, an underlying layer of sand or crushed stone screenings of a fraction of 0.7 or 0.4 mm, respectively, is laid. It is highly not recommended to use a cement-sand mixture for these purposes. In any case, the thickness of the underlying layer after compaction should be at least 3-5 cm. It is leveled so that the paving stones laid on it are approximately 1 cm higher than the calculated level. These actions compensate for the difference in heights of individual elements of the material. Finally, the topping is compacted after paving the paving stones.

Required Tools

Before laying paving stones, you should prepare the required elements and fixtures. This:

- goggles and gloves;

- rubber mallet and broom;

- wooden and metal pegs;

- spade and garden rake;

- roulette and level;

- tub and trowel;

- grinder and special diamond discs for cutting stone;

- wheelbarrow and stretcher;

- vibrating plate with overlay.

Drainage

This issue is resolved even before the foundation is prepared. For its successful implementation, it is necessary to set the correct slopes for the coating:

- paving in rows - 1 cm / m;

- laying with a pattern - 1.5 cm / m;

- to drain liquid from the blind area - 3 cm / m.

These slopes may require additional excavation or backfilling.

Installation technology and basic rules

So, laying paving stones. The technology involves the installation of curbs or curbs, which avoid damage to the backfill. An already paved surface is taken as a support for the next rows of material, that is, laying is done from the edges to the center of the site.

It is important to monitor the even distribution of the tiles using a regular cord for this. If the site is intended for the regular movement of cars and other vehicles, then the material is laid at an angle to the direction of their movement (diagonal laying of paving stones). The paving technology allows you to evenly distribute pressure on each element, making the surface more stable and reliable. At the same time, noise from the wheels of cars is also reduced. At the edges of the area where the junction between the curb and the paving elements passes, with the help of a special saw, the tile is cut so that it fits more tightly. But it is important to remember that it is advisable to cut the paving stones no more than half. Laying paving stones with your own hands is a long and painstaking task. In one shift, a person is able to master 30-40 m 2 of area, so you need to correctly calculate the time and effort if you decide to do everything yourself.

Since tile production technologies vary, individual elements of the material may have different shades. This is especially true in large areas. A noticeable difference can be avoided. To do this, it is recommended to lay out the material simultaneously from several pallets, at least three.

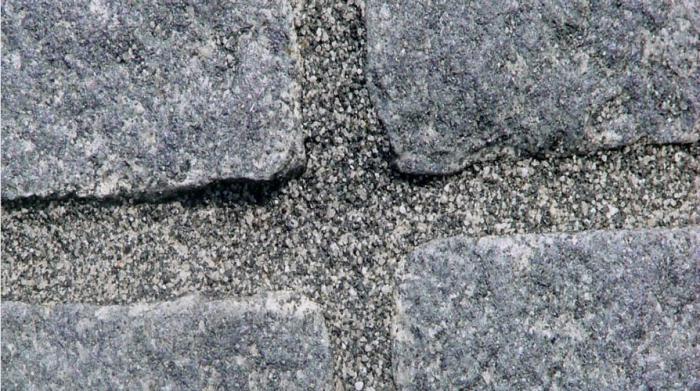

Seam filling

After completing the work on laying the paving stones, they begin to fill the formed joints. The material used must ensure uniform load transfer to all elements of the coating. To do this, it is recommended to use clean sand with a fraction of 0.2 mm, since coarse-grained sand does not always fill the seams evenly and gets stuck, and clay impurities can cause stains on the paving stones. Excess sand is removed before vibrocompaction. The process can be repeated many times, and to facilitate and speed up the process, the seams are watered.

It is important to observe certain intervals between the elements of the coating, since aesthetics is one of the main advantages that paving stones have. Photos of the material confirm this. In addition, small seams between the tiles allow them to interact and evenly distribute the load. The spacing between tiles minimizes tile dimensional variations and compensates for possible dimensional changes due to temperature changes.

For pedestrian areas, the dimensions of the seams should be approximately 2-3 mm, and for areas where cars will regularly drive, this figure is 3-5 mm. Adjust intervals should be in the process of work, any deviations need to be corrected.

vibratory seal

The last step is surface compaction. It is carried out with a special vibrator, which allows to achieve the planned level and stability of the coating. The procedure is carried out from the edges to the center - in the same way as paving stones are laid. The price of such a car is decent, so it is advisable to rent it. After compaction, the joints are refilled with sand.

The result of the work is an even, smooth, stable coating, between the elements of which there are seams of the same size.

Exploitation

In winter, ice can be avoided with a broom and a wooden shovel. If the snow is not removed in time and ice appears, it is strictly forbidden to use iron tools. Even snowplows should have a rubber nozzle on the blade.

Paving stones are subject to all kinds of pollution. For example, car tires leave black streaks, while dust and dirt make the surface black and gray. You can clean the paving stones and return it to its original appearance with the help of special cleaning agents, which are not difficult to find.

The cost of paving stones varies in a wide price range. For example, the average price per square meter of granite paving stones is from 1400 rubles (chopped) to 5800 (full-sawn). Sandstone paving stones will cost 750-1600 rubles / m 2, and quartzite paving stones - 800-2000 rubles / m 2.