Mixing unit for underfloor heating and radiators. Mixing unit for underfloor heating: functions, device, accessories

Comfort in the house is one of the most important components of arranging your own home. It is not only a cozy environment and modern technology, but also high-quality ventilation, and most importantly, warmth and a good climate. It is this point that deserves special attention.

Modern technologies offer ample opportunities for heating the house, and along with traditional central heating, the “warm floor” system is increasingly being used. mixing unit for a warm floor with your own hands, this is only part of the work that you have to do.

The collector is a kind of connecting pipeline, distributes the coolant in various heating systems. In simple words, it is just a pipe that can connect and connect other pipelines.

On all such types of connections, threads are applied on both sides: external and internal. The price of such a device depends on the manufacturer and configuration.

IN heating system for a warm floor, the coolant is supplied to the collector, with the help of which it is distributed over all loops. After that, the coolant moves to the return manifold, which directs it to the boiler for heating. The process is repeated again.

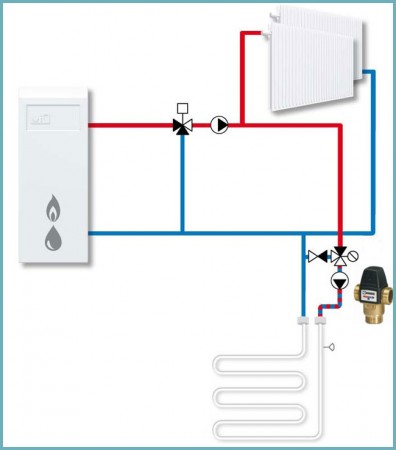

Scheme and principle of operation of the mixing unit

The mixing unit includes a pump and a valve. But more advanced configurations are often found.

The circulation pump may be located on the boiler itself, but its power will not be enough. For underfloor heating, it is necessary to put a separate pump on the mixing unit. In this way, the temperature will be freely regulated and lowered from 70-90 °C to 35-50 °C.

In addition, there is a fuse on the mixer without fail, which turns off the pump as soon as the temperature in the supply exceeds the set one.

In the supply pipe, the water reaches 85 °C. Legend:

- Three-way valve;

- Pump;

- Temperature sensor;

- Check valve.

The return line is from the manifold. The temperature of the coolant in it is 40 ° C. It has a non-return valve that prevents backflow of water.

Thus, when the thermostatic device is activated, the damper will automatically open, thereby mixing colder water from the return. After normalization of the temperature, the damper closes.

2-way mixing unit

A two-way or feed mixer works according to the principle described above. After the thermal head is triggered, it cuts off the flow hot water and mixes return water. The floor does not overheat, thereby increasing its service life.

This type of mixing unit has a small throughput, so the adjustment of the water supply occurs smoothly, without jumps. Most of the craftsmen prefer this particular type of mixer. But, unfortunately, it is not suitable for heating areas larger than 200 m².

Three-way valve

It plays the role of a checkpoint in combination with the functions of a bypass valve. But, unlike him, hot water is mixed with cold return inside the three-way. As a rule, such devices are equipped with thermostats.

Inside, between the return and supply pipes, there is a damper. By opening or closing it, the water supply is regulated.

Do-it-yourself installation and installation of a mixing unit for underfloor heating

In connection with high cost finished equipment for underfloor heating, the profitability of assembling such equipment with your own hands is quite high. Unfortunately, not everyone will be able to cope with this task, but further information will be useful in any case. So, the material that will be needed for installation:

- union nuts;

- nipples;

- air vent (manual);

- thermometers;

- check valve;

- circular pump;

- tees; Various types connections, etc.

The assembly technology consists in the installation of thermometers installed in the supply and check valves. Their task is to control the degrees of the transported liquid. The principle of operation of the remaining elements of the circuit has already been described earlier.

The pump, due to circulation, will support the process of heating water in the pipeline. Thanks to the installation of a bypass, the system will gain protection against overheating. The water drain valve, in turn, will protect the pipes from bursting in case of excess pressure.

After the assembly of the unit is completed, it is connected to the circuits using fittings. But before you start the system, you need to balance it.

Mounting Features:

- The assembled or factory mixing unit is mounted to the contour of the warm floor.

- Installation can be either left or right hand.

- The node can be attached in a special locker, in the room itself or in a specially designated room (boiler room).

- Install the pump first and temperature sensor.

- A mixing valve is connected to the supply pipe (“warm”), and a warm valve is connected to the return pipe.

- Balancing is done using test inclusions: at high or low temperature, it is respectively reduced / increased until it is normalized.

The underfloor heating is connected according to the diagram below. However, each connection case has its own characteristics. For example, with a one-pipe system, the bypass must be constantly open, but with a two-pipe system, this is not necessary.

Connection schemes differ in the presence and absence of additional elements, but this is not so important. The main thing is to know that valves, flow meters and thermostats must be installed on each group of collectors.

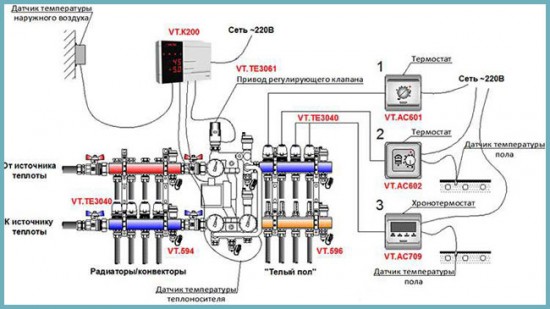

One of the "know-how" technologies is weather-compensated controllers. Thanks to them, the temperature of the warm floor is automatically regulated, depending on the weather outside. Special sensors every 20 seconds measure how many degrees it is outside and, based on this, they shift or do not shift the temperature of the warm floor by 4.5 °C.

At the end of the instructions, I would like to add a video that shows all the subtleties of installation:

Advantages of a warm floor with a mixing unit:

- Long service life. The only element in the system that is more prone to wear than the others is the pipe. The minimum term of its wear resistance is 50 years.

- Automated control, due to weather-dependent thermostats. The heating level is adjusted according to how cold it is outside at the current time.

- Ability to use manual mode. Suitable for those who prefer to control the temperature with their own hands.

- Impossibility of overheating of the system and rupture of pipes, due to the presence of temperature sensors and special valves.

- economy. When installing the system yourself, you can save a lot of money.

How to choose high-quality pipes for underfloor heating, read on

- why they are needed, how to choose, how to stack.

Correctly made calculation of a warm floor will allow not only to lay the system better, but also save money on materials. all the necessary formulas.

It is possible to provide full-fledged heating with the help of the "warm floor" system only where there are no serious frosts.

In the vast majority of cases, underfloor heating is combined with a classic radiator system.

But the lower heating cannot be brought to high rates (no more than 45 °), while the boiler can produce up to 100 ° C.

This is where the need arises for a special unit that will lower the temperature of the water entering the floor.

This collector is required part, but can become the most expensive element of the system. We will find out whether it is possible, in order to save money, to make a mixing unit for a warm floor with your own hands.

The main structural element is the mixing valve. It has three exits. Hot water is supplied to it from the boiler, for example, 80 ° C. For a warm floor, this is a lot (recommended 30-45 °).

The side outlet of the valve mixes the cooled coolant from the return to the hot water. From the boiler, the water supply is temporarily blocked, and the circulation goes in a small circle. When t drops to a predetermined value, the supply from the boiler resumes and hot water is mixed into the flow.

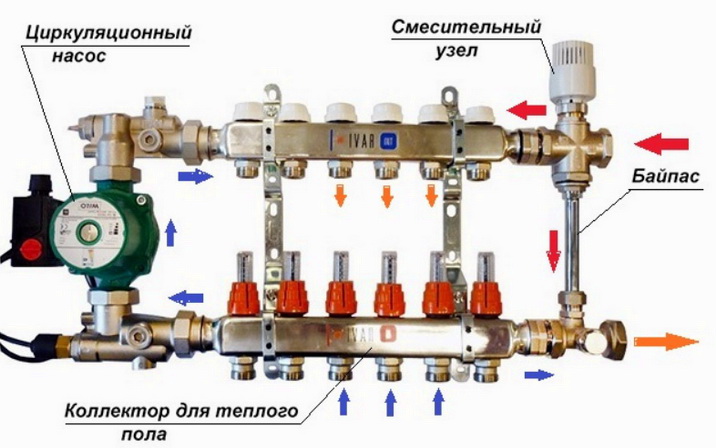

Components of the mixing unit

The thermal head sensor takes temperature readings. In factory models, it is immersed in a coolant; at self assembly, the sensor is fixed outside the pipe section where the control is carried out. This place is insulated so that the readings are more accurate, but the error will be 3-4 degrees (this must be taken into account when setting the temperature on the thermal head).

The thermal head, connected to the sensor, controls the incoming hot coolant and affects the amount of liquid passing through the valve, slightly opening and closing it.

Did you know that a water floor cannot be made in an apartment? Therefore, for apartment owners there is only one Alternative option underfloor heating devices - . Read about the benefits of an infrared floor, as well as installation features and system costs.

Read about how to organize a system with underfloor heating in the bathroom.

In the bathroom, in the kitchen and in the corridor, the floor is most often tiled, as it does not get wet, does not deform and is a practical coating. The only drawback is that the floor is always cold. Here we will consider which warm floor is better to put under the tile.

DIY mixer

Underfloor heating systems are not always obtained standard sizes and configurations. In practice, it may be necessary to distribute water to several collectors (on different floors, for example) or make other changes. Then it is better to purchase separate heating elements and install everything as it is more convenient in a particular case.

You will need:

- circulation pump;

- collectors - 2 pcs. (or 4, if on 2 floors);

- mixing valve (2-way or 3-way);

- ball valves 3 pcs.;

- thermal head with sensor;

- manometer;

- Mayevsky's crane;

- fitting;

- tees;

- nipples.

Assembly order

Having considered a three-way valve, we determine how the coolant will pass. Instead of a plug-plug, a thermal head is screwed on. We'll install the sensor later.

- A ball valve is installed at the hot water inlet (from the boiler).

- It connects to the inlet of the three-way valve, as indicated by the arrow.

- At the outlet of the 3-way valve, a supply branch to the warm floor. A circulation pump is installed here.

- At some distance from the pump, a pressure gauge is connected.

- Next is the distribution manifold on the floor. Here you select the area where the temperature sensor will be located. It is fixed with plastic clamps.

- Moving along the course of the coolant, we install the return manifold.

- Through a simple tee, we connect to the return inlet of the three-way valve (As a result, the valve should have: 1 - inlet from the boiler, 2 - return inlet, 3 - outlet to the heated floor of the mixed coolant).

- Through a tap in a simple tee, a return is made to the boiler.

In front of the collector at the highest point, you need to install a Mayevsky crane to release air, which inevitably forms in heating.

Mixing unit assembled

If the circuit branches differ in length, on the comb, at the outlet of each tube, you need to install a thermostat that will automatically maintain the same temperature (otherwise the shorter circuit will always be hotter than the long one). Thermostats are installed on the return manifold.

Between the boiler and this entire system, branches are made through the tees to the classic radiator system.

The place where the temperature sensor is attached to the pipe can be insulated with a piece of penofol, tightly wrapping it with tape.

For better control over heating, you can install a manifold with flow meters on each branch (on the supply). If one of the circuits is clogged, you will know this by reducing the flow of fluid.

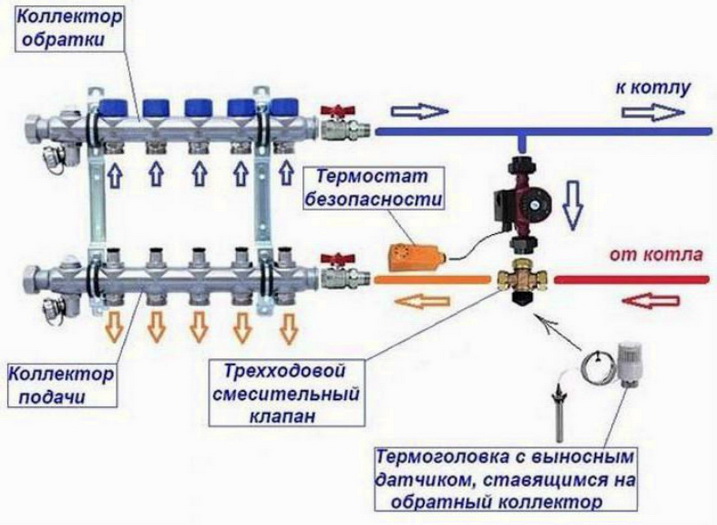

Three thermometers for more efficiency

If you install two more monitoring thermometers, this will increase Heating efficiency, avoid sudden drops and use the pump more carefully, without giving it an unnecessary load.

Places where you need to install thermometers (or pressure gauges with temperature readings):

- Between the pump and the supply manifold (as described above).

- On the return line: behind the manifold, to the tee.

- Between boiler and mixing valve.

The difference in temperature readings No. 1 and 2 should ideally be 5 ° C.

If the difference t is greater, then the pump power is not enough, it must be transferred to an increased operating mode.

If the difference is smaller, you can reduce the pump power.

The third thermometer shows the t that the boiler produces.

The purpose of the mixing unit is to prepare a coolant with a temperature of +30 - +50 degrees for supply to floor heating. The temperature in the heating system is +60 - +80 degrees. To reduce it, to make the coolant cold enough to be supplied to the warm floor, a mixing unit is needed.

There is no need if the boiler solar collector... low temperature heat transfer medium will be prepared. Moreover, the heat source must quickly change the temperature of the heated liquid.

Also, the device is not needed if it is possible to apply the scheme for adjusting the warm floor with flow controllers. Read more...

How does a mixing unit for underfloor heating work

The basis of the node is a three-way valve, which is connected according to the following scheme. Hot supply +80 degrees is supplied to the input, for mixing, a return line from underfloor heating +30 degrees is connected. The valve opens so that the liquids are mixed in a certain proportion, with a temperature output of +45 degrees (for example). But this temperature can be regulated.

Typical scheme connection of the mixing unit.

The valve is controlled by a thermal head, it moves the stem of this device. Its sensor is usually installed on the return of the underfloor heating collector.

Thermal head with remote sensor:

Schemes of mixing units from manufacturers can be more complex and “not obvious” at first glance, for example:

Circulation pump and other equipment

The pump in the boiler or in the radiator system will not be able to ensure the operation of the underfloor heating mixing unit.In order for the unit to work, an additional pump must be installed according to the "behind the valve" scheme, distilling the coolant along the collector circuit.

The mixing unit is usually equipped with the following equipment:

- bypass (thin connecting tube) between supply and return. A bypass is needed in case all the underfloor heating circuits are blocked on the collector so as not to overload the pump.

- emergency temperature valve. If the regulating thermal head fails and opens the supply, then to protect the screed and floor covering from a temperature of 80 degrees, an emergency valve is installed behind the mixing unit according to the scheme. Or a supply thermostat that interrupts the operation of the pump when the temperature rises critically.

Additional possible equipment:

- the air vent removes air in front of the underfloor heating collector, which can come from the radiator system;

- a cleaning filter is never superfluous;

- pressure gauge, indicates the pressure after the pump;

- thermometer for visual monitoring of the operation of the mixing unit (thermometers can be installed on the supply and on the return of the manifold itself)

Design options

Manufacturers offer ready-made mixing units, often already assembled with a manifold, and even with a cabinet. Such a kit will pull on a rounded amount of money, but the equipment will (should) work well together, there is no need for selection, adjustment, installation.

The pump can be installed both on the supply and on the return of the underfloor heating, or on the bypass supplying the return to the valve - it does not matter.

The three-way valve can be installed both on the supply and on the return. But the choice of its location depends on its design - mixes or separates? - more precisely, the three-way valve is selected in accordance with the project.

When choosing a valve, look at the arrows on the body indicating the movement of the fluid, correlate with the decisions made.

A design variant with a heat exchanger is possible, then the coolant in the warm floor is its own, and in the system that gives off heat - its own (then you need expansion tank!). Such a system allows you to take energy from centralized systems heating. And in some cases, to make underfloor heating in apartments without a direct intake of the communal coolant.

Basically, manufacturers offer a set for underfloor heating - a mixing unit grouped with a collector.

Is it possible to make a mixing unit with your own hands

You can save money if you make the mixing unit yourself. In this case, as a rule, cheaper analogues of equipment are used, usually made in Russia or from Asia.It is important to choose equipment for performance. Mostly in private homes, two sizes of a three-way valve are used.

The photo shows a valve with a capacity of up to 2 cubic meters. per hour, and this, as a rule, is the area of \u200b\u200bthe warm floor up to 80 square meters.

In most cases, you will need an option with a capacity of 4 cubic meters per hour, and, accordingly, for a heated floor area of 100 - 200 square meters.

Also, when choosing a ready-made mixing unit, pay attention to its performance.

Wiring diagram

As a rule, the mixing unit is directly attached to the floor heating collector and is located in a special cabinet.But between the mixing unit and the collector, pipes of reasonable length can be installed, i.e. place the mixing unit in one room, for example, by the boiler, and the collector in another, if it is more profitable in terms of free space.

The mixing unit is connected to the radiator system in the same way as one radiator or a group of radiators.

But it is advisable to make the connection closer to the boiler in order to exclude influence (on / off, hydraulic resistance, cooling) in the radiator network.

The underfloor heating mixing unit can also be connected to an outdated one-pipe system, just like a radiator, according to the "one pipe" scheme. But you can also turn it on in series, providing a bypass for the flow of liquid to the next radiators past the node.

As a rule, warm floors cannot be connected to a gravity heating system, since an additional coolant flow rate of 2-5 m3 per hour is not provided and high blood pressure. To connect the mixing unit, this system must be converted into a closed, forced one.

What can replace

If the boiler itself heats the coolant to 30 - 50 degrees, then the mixing unit is not needed at all. Modern super-economical condensing boilers, which are even forced to be installed in Europe, are just designed for about this temperature.Heating with condensing boiler and focus on heating warm floors, when using a low-temperature radiator network, is the most economical and progressive.

In short circuits (45m and less), it is possible to adjust the temperature of underfloor heating with RTL taps, without a mixing unit at all.

Also, "people say" that you can replace expensive RTL heads with a cheap thermal relay, put it on the return manifold and make the pump turn off as soon as the temperature exceeds the set 35 degrees. But it seems that in this case there is a great risk of destroying the screed and flooring high temperature in case of incorrect operation and "protracted start-up". However, such a solution is "the cheapest, most budget hydraulics for underfloor heating."

Today, among the heating systems used in everyday life, warm water floors are gaining popularity. increased attention on the part of consumers to this method of heating is due to the high efficiency of heating floors, especially when the emphasis is on quality interior decoration residential premises. Heating radiators do not always look aesthetically pleasing, while the water circuit hidden in the floor is completely invisible.

Bribes in this case and installation heating equipment. With proper planning and compliance with all the necessary technological subtleties, make underfloor heating in own house quite realistic and within the power of everyone. In order to succeed, it is enough to have an idea of how the underfloor heating works, which is included in the equipment. In the process of work, you will have to face not only the choice of the method of heating the coolant, the selection and laying of water circuit pipes and screed equipment. The key element of the "warm water floor" heating system is the underfloor heating mixing unit.

What is this equipment? What is its design and purpose? Let's deal with these issues in more detail.

Underfloor heating today can be found in almost any residential area. City apartments, if allowed design features a residential facility are often heated in this way. In many private houses, in cottages, water floors are a common phenomenon. Due to the design features, the underfloor heating system can be used both as a full-fledged, main heating of residential premises, and as an auxiliary heating option. Competent installation, the availability of appropriate equipment will allow you to use water floors with maximum efficiency. And it will help you with this, a mixing unit for your warm floors.

Warm water floors is a low-temperature heating system. Unlike radiators, normal operation heating water circuits, it is necessary to have a coolant whose temperature varies between 35-55 0 C. The water that circulates in the system central heating much hotter, not to mention the coolant heated as a result of the operation of the heating boiler. The work of preparing water for water circuits is performed by a mixing unit. On top of that, through the system of collector inputs, the distribution of the coolant through the underfloor heating pipeline is carried out.

On a note: it should be said that a mixing unit or a mixing unit is necessary when you have expressed a desire to make heating in your house through underfloor heating. For other heating options, this technique is not required.

The principle of operation of the mixing unit

Like all other heating systems that use a liquid coolant, heating due to water-heated floors works in a similar way:

- heating source (autonomous boiler or central heating riser);

- supply and return pipelines, water circuits laid in the floor of a heated room;

- devices and instruments of the regulatory group.

Water is heated by the operation of the boiler or supplied to the system from the DHW line and central heating. In an autonomous boiler, water is heated to a temperature of 75-95 0 C, in the central heating system the water temperature is slightly lower, 55-75 0 C. In accordance with sanitary standards ideal temperature floor heating should be 31 0 C, due to which a comfortable stay zone is created in the heated room. In order to achieve such temperature parameters, water heated to a temperature of 35-55 0 C is supplied to the loops of the water floor. thermal energy, giving out optimal temperature indicators on the floor surface.

In order to direct the flow of water into the water circuit desired temperature, a mixing unit for underfloor heating is installed. Otherwise, the underfloor heating system will be a waste of money. Without adjusting the temperature of the coolant, your floor will turn into a hot pan, and concrete screed and the floor covering will soon become unusable.

Important! It should be remembered that the mixing unit can only work if ordinary water circulates in the heating system.

The unit is mounted in the immediate vicinity of the heated room, where the heating circuit loops come to the surface. The equipment is connected to both pipes, to the hot water supply pipeline and to the return flow line. As a result of its work, an excessively hot coolant is mixed with cooled, cooled waste water, resulting in optimal temperature water for heating pipes.

Important! If the water in the system is not so critical for underfloor heating, it is not necessary to install a mixing unit. If an autonomous boiler works for heating and provides hot water for domestic purposes, you cannot do without a mixing unit.

It would be appropriate to say. Do not confuse the mixing unit and the manifold. The first is a set of equipment, each of which individually performs the functions assigned to it. Collector is integral part mixing unit and is designed to collect and distribute water flows in the heating system.

Based on the configuration, the principle of operation of the mixing unit follows.

The heat carrier from the heating source enters the collector. The presence of a safety valve and a thermostat does not allow hot water to move freely further. At a high water temperature, the automatic mode is activated. The inlet valve opens and hot fluid is added to the hot stream. cold water coming in the opposite direction. When the water reaches the required temperature values, the valve automatically closes, stopping the supply of hot water to the system. This process occurs constantly and uninterruptedly during the operation of the heating system.

Mixing unit completeness

The principle of operation of the equipment is simple and clear. Another thing is what devices and equipment provides the functionality of the entire unit. The easiest option that you can do yourself is a mixer equipped with a manifold, a safety valve and circulation pump.

The first performs the task of distributing the flow through the water pipes of the underfloor heating. The safety valve provides hot water supply to the collector and control of the water heating temperature.

The circulation pump communicates the required speed to the water flow, ensuring the intensity and uniformity of water supply to the underfloor heating system.

More complex structure mixer is a whole set of additional elements. In addition to the devices already mentioned, a manifold, a safety valve and a supply pump, the kit of a conventional mixing unit includes:

- Bypass - an element that protects your equipment from overload and overheating;

- Drain, bleed valve;

- Shut-off valve;

- Air vents;

- Thermal relay.

The mixing unit should be a compact design that can be successfully hidden in a manifold cabinet.

On a note: if it is planned to equip underfloor heating in several rooms, each of them will require its own separate mixing unit. You can install one single unit for all heating circuits, only in this case it is better to use a collector with a large number inputs and an additional amount of safety fittings.

Mixers are usually equipped with three-way and two-way valves. The second is also called the supply valve. Thanks to its filling, thermostat and sensor, the valve reacts to the slightest change in the temperature of water heating in the system, opening or shutting off the water supply.

For heated rooms with an area of more than 200 m2, the use of a two-way valve is not recommended.

Has several functions. Due to its design, the valve is capable of diverting and mixing. Thanks to such a device in the mixing unit, the hot water coming from the heating device is mixed with the return. Usually, valves with servo drives are placed on the mixture, which independently, in automatic mode, regulate the level of mixture. Complementing the mixing block with a three-way valve complete with a weather-dependent controller, you will receive a fully automated heating temperature control system. In addition, the three-way valve is designed to work with warm floors of a large area.

If you want to save on equipment, use manual adjustment valves. Saving on automation, you get for yourself extra hassle. With manual adjustment, it is quite difficult to determine the optimal flow of the coolant in the system. Automation solves these issues easier and faster.

Installation of the mixing unit. Installation Features

At correct selection components, subject to all the necessary technical conditions, the installation of the mixer should not cause difficulties. Having determined the location of the mixing unit, having simulated the design of the manifold cabinet, start the assembly.

For the future. The underfloor heating control unit must have free access. Otherwise, you will have to face difficulties during operation.

First, the pipelines coming from the heater are connected. The collector is installed next. At the end, the system can be equipped with sensors for adjusting pressure, pressure and thermometers. It is important to determine the way the collector combs are located. The type of heating source your system is connected to determines how the distribution manifolds are connected. It can be an end connection or a regular one, top and bottom.

For the hot water supply line, it is better to use metal-plastic pipes or polymer materials. These components are able to cope with pressure surges in the system, and perfectly withstand high temperatures.

Connection of equipment to water circuits is carried out in a clear sequence using fittings. Pipes are connected to the blue inlet pipes, through which the cooled water flows in the opposite direction. A water loop is connected to the red pipes, which provides floor heating in a heated room.

If you are planning to make a warm floor for heating large areas, you will definitely need a circulation pump. The large length of the water circuit, the large number of bends and the small diameter of the heating pipe lead to the fact that the circulation of the coolant in the system noticeably weakens. By installing a circulation pump, you will ensure the normal supply of prepared water to the heating circuits. It is recommended to install the pump at the beginning of the mixing unit, where the supply pipe is suitable and the return is connected.

The pump is installed strictly horizontal position. It is recommended to install pumps with several speed modes. These models allow you to manually determine the required feed rate and flow rate.

In custody

Having become acquainted with the importance of the mixing unit for the “warm water floors” heating system, how its work is arranged, we can say a few words about setting up the equipment. Without proper training, it is better to entrust such a procedure to specialists - heat engineers. Despite the fact that the installation of a warm floor and the installation of a mixer are tasks that you can handle on your own, setting up a regulating group requires appropriate qualifications and knowledge.

Dl general information Let's note a couple of steps that are associated with the process of setting up the mixer.

The calculations will be something like this:

Where, t1 is the temperature of the water in the supply pipe from an autonomous boiler or CH system;

t2supply is the water temperature at the inlet to the water circuit;

t2return is the return water temperature coming from the water circuit loop;

Kvt is a generally accepted coefficient, which is equal to the value of 0.9.

We take the average numbers for calculations, for the operation of an autonomous boiler:

t2 supply = 45 °С,

t2arr = 35 °С.

As a result, we get:

This is the value that we set on the balancing valve.

Next, we set up the pump, taking into account the capacity of the balancing valve and the required intensity of water flow. If you cannot configure the pump taking into account the optimal parameters, install on it minimal modes work. In the future, when it becomes clear that the operating speed of the pump is not enough, reset the unit to a higher speed.

- The last stage is connected with balancing the water floor loop. Dealing with this task balancing valves. If you have one branch of the heating circuit, balancing is not required.

In conclusion, it should be said that the assembled mixing unit and connected to the system requires mandatory tying with the entire heating system. Keeping everything necessary instructions and recommendations of specialists, entrusting the performance of hydraulic and thermal calculations to specialists, you can count on a successful outcome of your event. The mixing unit, assembled according to all the rules, will allow your home system heating as efficiently as possible. In addition, you will significantly increase the level of comfort in the house and your own safety.

IN last years heating using radiators is becoming less and less popular, and it is being replaced by a more advanced option - underfloor heating systems. Moreover, with the help of them you can heat not only a specific room, for example, a nursery, but the entire building as a whole.

A warm floor can complement the main heating system, but there is also a stand-alone version of this system, since when used, the liquid undergoes special training before reaching the heating circuit. The solution of such a problem is the combination of two elements presented mixing unit for underfloor heating and pumping group. Next, we will take a closer look at this element, get acquainted with the principle of its operation and the features of connecting the collector.

The purpose of the mixing unit for underfloor heating

In my own way appearance mixing mixing unit is a group or chain of pipelines that fit in a strictly defined sequence used to solve one problem - combining two different fluid flows into one common one.

There are three options for mixing the coolant:

Among all the listed types, sequential mixing seems to be the best option. This choice is primarily due to its high performance, since almost all of the recycled water reaches the consumer.

In some cases, a parallel option is allowed. In this case fluctuating fluid flow. However, this drawback can be eliminated by installing a two-way valve, which can be adjusted in the most optimal way.

Collector circuit

Several schemes can be selected for mounting the collector group. One of them will be shown below.

This scheme requires the use of certain elements:

When using a similar scheme, the water supply is provided by a circulation pump. This continues until it succeeds reach the desired temperature. After that, automation begins to operate, which leads to blocking the access of water with the help of valves. This terminates the process. It must be borne in mind that when doing the installation with your own hands, you should take care of the drainage device and the air vent system.

Selecting and connecting a collector

When choosing a collector model, it is necessary to take into account, first of all, the location of the underfloor heating and the installation method used. All this will subsequently affect the costs, as well as will affect the safety level of the equipment. When installing a manifold mixing assembly, be aware that it has a low level of protection, since it contains liquid that has a different temperature.

When choosing a collector model, it is necessary to take into account, first of all, the location of the underfloor heating and the installation method used. All this will subsequently affect the costs, as well as will affect the safety level of the equipment. When installing a manifold mixing assembly, be aware that it has a low level of protection, since it contains liquid that has a different temperature.

When the various flows converge into one common one, the temperature stabilizes, and after that it is necessary to ensure that it is maintained at the required level. The efficiency of the underfloor heating system is influenced by materials used and build quality. For this reason, it is necessary to carefully choose not only the mixing unit for underfloor heating, but also pump equipment and thermostat.

What to look for when buying?

Distribution manifolds offered for sale may vary in price, which may depend on the material used. There are models on the market that are overwhelmingly made of brass. At the same time, there are products made on the basis of stainless steel in stores.

Another factor that determines the cost of products is the complexity of the equipment. If you analyze the range of collectors available today, then among them you can find models the simplest design, providing a minimum set of elements, as well as systems that are equipped not only with the basic set, but also additional elements protection, drain cocks, sensors for adjusting and monitoring the flow of coolant.

Another factor that determines the cost of products is the complexity of the equipment. If you analyze the range of collectors available today, then among them you can find models the simplest design, providing a minimum set of elements, as well as systems that are equipped not only with the basic set, but also additional elements protection, drain cocks, sensors for adjusting and monitoring the flow of coolant.

The vast majority of buyers quite often opt for equipment that has a thermal control mixing unit in its design. The latter is equipped a set of temperature sensors and other measuring devices. The main task of automation is reduced to the choice of the optimal mode for the process of distribution of the coolant. At certain times, the bleed valves may operate or the fluid flow may be restricted. If we consider the set standard model, then it is equipped with several thermometers, thanks to which it becomes possible to reduce heat loss.

For underfloor heating systems that provide for several heating circuits, it is advisable to install a special thermoregulation device on each of them, the designs of which include combs and flow sensors. Such collectors must be equipped air vent, mixing valves, thermometer case and a thermal head, which has a probe that allows you to run this element into the liquid. The valve creates an opportunity for access to the underfloor heating circuit of the required volume of liquid heated to a high temperature. At the same time, the thermal head ensures that there is no process disturbance, protecting against malfunctions.

Key parameters

Individual consumers great importance pay the price of the chosen device. However, when choosing, you have to pay attention to other points that are also important:

- area of the room;

- purpose of use.

Let's say if it's a room small size, for example, a bathroom, then you can limit yourself to a standard plastic manifold equipped with a simple temperature setting system.

Let's say if it's a room small size, for example, a bathroom, then you can limit yourself to a standard plastic manifold equipped with a simple temperature setting system.

Sometimes it may be necessary to use flow meters. In this case, the buyer will need to purchase them separately by paying a small amount of money. If you have to deal with a fairly spacious room, then the most best option – use of high reliability mixers, with a choice of temperature, which allows the best way adjust the contour of the warm floor.

The location of the collector node in the underfloor heating system

Even before starting work on installing a floor heating collector, you should take care of installation of a metal protective cabinet, which may provide for open or closed version execution. In some cases, the first option is chosen, since in this case access to it is simplified, although this negatively affects the service life of parts and connections that do not have reliable protection.

When solving the issue with a place for a cabinet, it is necessary to take into account the placement of the contours of the water floor.  If there are several branches, it is best allocate space for the closet in the center, and it should be on the same distance away from the working circuits and located as close as possible to main pipelines. By choosing a similar placement option for this element, you can be sure that the maximum performance will be ensured during the implementation of the hydraulic process.

If there are several branches, it is best allocate space for the closet in the center, and it should be on the same distance away from the working circuits and located as close as possible to main pipelines. By choosing a similar placement option for this element, you can be sure that the maximum performance will be ensured during the implementation of the hydraulic process.

It is best if the equipment is installed in a niche, limited on both sides by walls, where there is an opportunity for accurate installation of collector elements and pipeline supply. Sometimes underfloor heating is installed in all areas of the house. In this case, when installing the heating system in rooms with the largest area, it is necessary to bring separate distribution units.

Features of equipment installation

You can get theoretical training in installation and configuration of equipment today without any problems, given the presence on the Internet of a large number similar instructions. One of these schemes will be considered below. underfloor heating collector connections. Using it, you can independently assemble the system by connecting key elements to each other - a pipeline, a distribution unit and a boiler.

The first step is to install a thermometer and stopcocks with which each circuit exit should be equipped. Most often, these elements, the main purpose of which is to adjust the operation of the supply and return, are presented as part of a manifold set. If you adhere to the chosen scheme, then you can minimal cost time and without errors, install the distribution unit, and in addition, connect pipes for supplying and draining fluid. At the same time, this will create conditions for turning off any of the heating circuits at any time.

The first step is to install a thermometer and stopcocks with which each circuit exit should be equipped. Most often, these elements, the main purpose of which is to adjust the operation of the supply and return, are presented as part of a manifold set. If you adhere to the chosen scheme, then you can minimal cost time and without errors, install the distribution unit, and in addition, connect pipes for supplying and draining fluid. At the same time, this will create conditions for turning off any of the heating circuits at any time.

Compressor fittings are used to connect the elements. Often separate connections mounted with standard kit, represented by a nut, a bushing and an annular clamp. If there are discrepancies in the diameter of the elements used, their connection is carried out using adapters.

Conclusion

To provide effective work underfloor heating systems should be used by all necessary elements, including a mixing unit for underfloor heating. This element can affect the operating parameters of the system, allowing you to set the most optimal indicators for them.

To provide effective work underfloor heating systems should be used by all necessary elements, including a mixing unit for underfloor heating. This element can affect the operating parameters of the system, allowing you to set the most optimal indicators for them.

However, in order for such an element of the underfloor heating system to bring tangible benefits from use, it is necessary to properly install it. The scheme for connecting such a node to the system allows you to solve this problem without errors, due to which the owner will have the opportunity to adjust the operation of the heating system at will at any time.