Consumption of silicate plaster per 1 m2. How to calculate the consumption of gypsum plaster

When the walls of the house are fully prepared for leveling and measured, it is the turn to purchase plaster mixtures. At the same time, it is important to calculate everything correctly and, if possible, take care of reducing the plaster layer to an acceptable minimum.

What does the expense depend on?

It must be indicated by the manufacturer on the bag or plastic container. However, these characteristics are quite approximate and may vary by 1-2 kg/m 2 . After all, all the compositions are quite different, and their specific gravity different even within the same product group various brands. For preliminary calculation You can use indicative numbers.

1. Dry mixes.

- Cement.

The consumption of cement-sand plaster is very large: up to 18 kg for the Osnovit brand and about 16 kg for Litokol. The cement Knauf Diamant and Bergauf differ in average weight in terms of m 2, and the smallest has Keraflex - only 15.5 kg.

- Gypsum.

Average figures for light gypsum paste are from 8 to 10 kg per centimeter-thick square. Knauf Rotband and Prospectors have the minimum share. Average consumption gypsum plaster Rotband per 1 m 2 is 8.5 kg. The heaviest is Bau Putz from Bergauf - up to 13 kg / m 2 with a thickness of one centimeter.

Average figures for light gypsum paste are from 8 to 10 kg per centimeter-thick square. Knauf Rotband and Prospectors have the minimum share. Average consumption gypsum plaster Rotband per 1 m 2 is 8.5 kg. The heaviest is Bau Putz from Bergauf - up to 13 kg / m 2 with a thickness of one centimeter.

For gypsum solutions such as Rotband, which have to be applied in a particularly thick layer, the consumption is of great importance. For example, most of the walls in panel houses you have to level it by 3-5 cm. That is, a whole bag of Rotband will go to each square.

The thickness of the required solution layer will determine the height deviations at different points on the surface, but this value can be adjusted downward. To save a decent amount plaster mixture, large protrusions should be cut off.

- Terrazitic.

These cement-lime compositions are one of the few decorative coatings sold dry. Due to the large amount of mineral additives, plaster sins with a high specific gravity - about 2 kg / m 2 when applied with a layer of only 1 mm. But a solid carpet of marble, mica and quartz chips looks luxurious both on the facade and in the interior.

For dry mixes, the consumption also varies depending on the volume of water in the preparation of the solution. So it will be difficult to get an exact figure when calculating. Although with a bag weight of 25-30 kg, deviations will not be fundamental, it is very important to correctly determine right amount packages.

Do not forget that the manufacturer's instructions often give the consumption per centimeter layer. That is, with a thickness of 2 cm, the plaster will need twice as much for leveling.

2. Ready structural solutions.

- silicate.

For the most part, these are ready-made mixtures for outdoor work with large aggregates, the so-called pebble. The consumption of plasters per 1 m2 will depend on the size of these pebbles. With an inclusion size of 2 mm, at least 2.7 kg of Ceresit coating will take per square of the surface. 3 mm grains of Baumite will weigh the solution up to 3.9 kg / m 2. Given the considerable cost of silicate plaster, these are quite serious numbers, but in fact, a lot of it will not be needed. It is applied with a minimum layer, the thickness of which does not exceed the grain size.

- Acrylic.

Their consumption is completely dependent on the mineral aggregate, and therefore it is easy to calculate. Each millimeter of granularity corresponds to 1.0-1.2 kg of the specific gravity of the entire composition. With an increase in the grain fraction, the required amount of the mixture will also increase in direct proportion.

![]()

- Silicone.

The most expensive class of modern plaster solutions with wonderful operational characteristics. They are used both for interior work and for facade decoration. They are used not so much for protective as for decorative purposes.

To reduce the cost of the coating, mineral granules are added to it, which in turn make the plaster heavier. As a result, the consumption of the finished mixture ranges from 2-4 kg with a filler size of 1.5 to 3 mm.

The sizes of mineral inclusions proportionally increase the specific gravity of the coating. That is, the larger the fraction of granules that determine the texture, the more plaster will have to be used to finish 1 m 2.

Separately, it is necessary to specify the flow rate at the stage of its selection. For example, "Venetian" per 1 m 2 may need only 0.2-0.7 kg, and the facade "bark beetle" - 3-4 kg. Reduce Layer decorative plaster possible due to better surface preparation. True, for this you will have to additionally calculate the required amount of material for fine alignment. But in any case, this will be preferable and cheaper than overspending expensive plaster.

On porous and highly absorbent surfaces, in order to reduce the consumption per m 2 with a thickness of 1 cm of the plaster mixture, special insulating primers must be used. They will not allow moisture from the mortar to soak into the base, weakening the plaster layer, and provide more reliable adhesion to the wall.

In order to determine as accurately as possible the size of the plaster layer for leveling the wall, it is better to take measurements after marking and installing the beacons. Having learned the “depth” of the future coverage at several of the most problematic points, the measurement results should be added up and divided by their number. The more measurements you take, the more accurate the result will be.

For each surface, the thickness of the plaster layer is calculated separately. In this case, it is necessary to add the height of the beacon profile - 6-10 mm. That is why it is recommended to install beacons in the "lowest" sections of the wall in order to reduce consumption by 1 m 2.

No matter how accurate the calculation is, in the process of work, inconsistencies in theory and practice may be found. Therefore, when buying, it is still better to take a mixture of 5-10% more than it is supposed to be used.

Almost no repair is complete without plastering surfaces, and no purchase is made without calculating the required amount of the mixture. The ability to correctly calculate the consumption of gypsum plaster for square meter allows you to make an objective estimate of work and plan repair costs. The desire to avoid mistakes at the calculation stage is quite natural, because the repeated purchase of heavy material entails additional delivery costs, and the surplus will gather dust in the bins for years. Let's talk about the algorithm for calculating the required amount of gypsum mixture for plastering.

Factors determining the consumption of gypsum plaster per 1 m2

The choice of gypsum mixtures as a topic for conversation is not accidental, since they are most common in preparing premises for final finishing. Skillful hands with their help create absolutely smooth surfaces that correct existing defects. The homogeneous texture forms a smooth plane without roughness, ready for painting or other types of finishing coats.

Even if you do not plan to make repairs yourself, basic knowledge of how to calculate the amount of building materials has not bothered anyone. They will allow to control and regulate the work of builders, building a constructive dialogue with any "highly qualified ultra-professionals". So, the total amount of purchase depends on:

- Work area;

- wall material;

- Curvature of the walls;

- Building material manufacturer.

With the area of work, everything is relatively clear. The dependence is direct - the larger the area to be processed, the more mixture will need to be applied to it.

The chosen manufacturer of the building material also affects the final result of the calculations. The packages indicate the consumption rate of gypsum plaster per 1 m² when applied with a layer of 1 cm. So before you take on the calculator, you should decide on the brand of the mixture.

It would seem, what's the difference from what the wall is built, if you still align it? There is a difference, the recommended minimum layer for brick wall is 10 mm, while for a concrete wall a 5 mm thickness is sufficient. This difference is due to the fact that brickwork there is a possibility of translucence of the seams through a thinly applied layer. wooden surfaces rarely plastered, but if there is such a task, the thickness of the layer at the base of the wall is made at least 25 mm.

Surface curvature and consumption of gypsum plaster per 1 m2 of wall

The curvature of the walls is the eternal scourge of modern and not very modern construction, worthy of a separate section. I don’t want to go unfounded, and therefore we will dance from established norms. We open SNiP 3.04.01-87, and we see that the plastered surface may have a deviation of 1 m vertically and horizontally from 1 to 3 mm.

The spread of the standard by 3 times depends on what level of work we are applying for - simple, improved or high-quality (we want high-quality, and then how it will turn out). This means that everything that exceeds these very 3 mm must be leveled, and the degree of obstruction and curvature of the walls is directly proportional to the number of packages that need to be purchased. Do not forget about the cavities and tubercles, which will also have to be hidden.

To determine the degree of curvature, and, accordingly, the sufficient thickness of the plaster layer, the walls are hung. This operation allows you to translate into the language of numbers all the existing irregularities and deviations, and outline the future ideal plane.

Hanging the walls - we determine the consumption of gypsum plaster per 1 sq m

Careful hanging is the alpha and omega of surface leveling. Before proceeding with this operation, the wall should be prepared for plastering:

- Remove the old coating (painting, wallpaper);

- Knock down mortar protruding in the seams of the masonry (for new walls);

- Clean up the bumps, if possible;

- Remove crumbling areas.

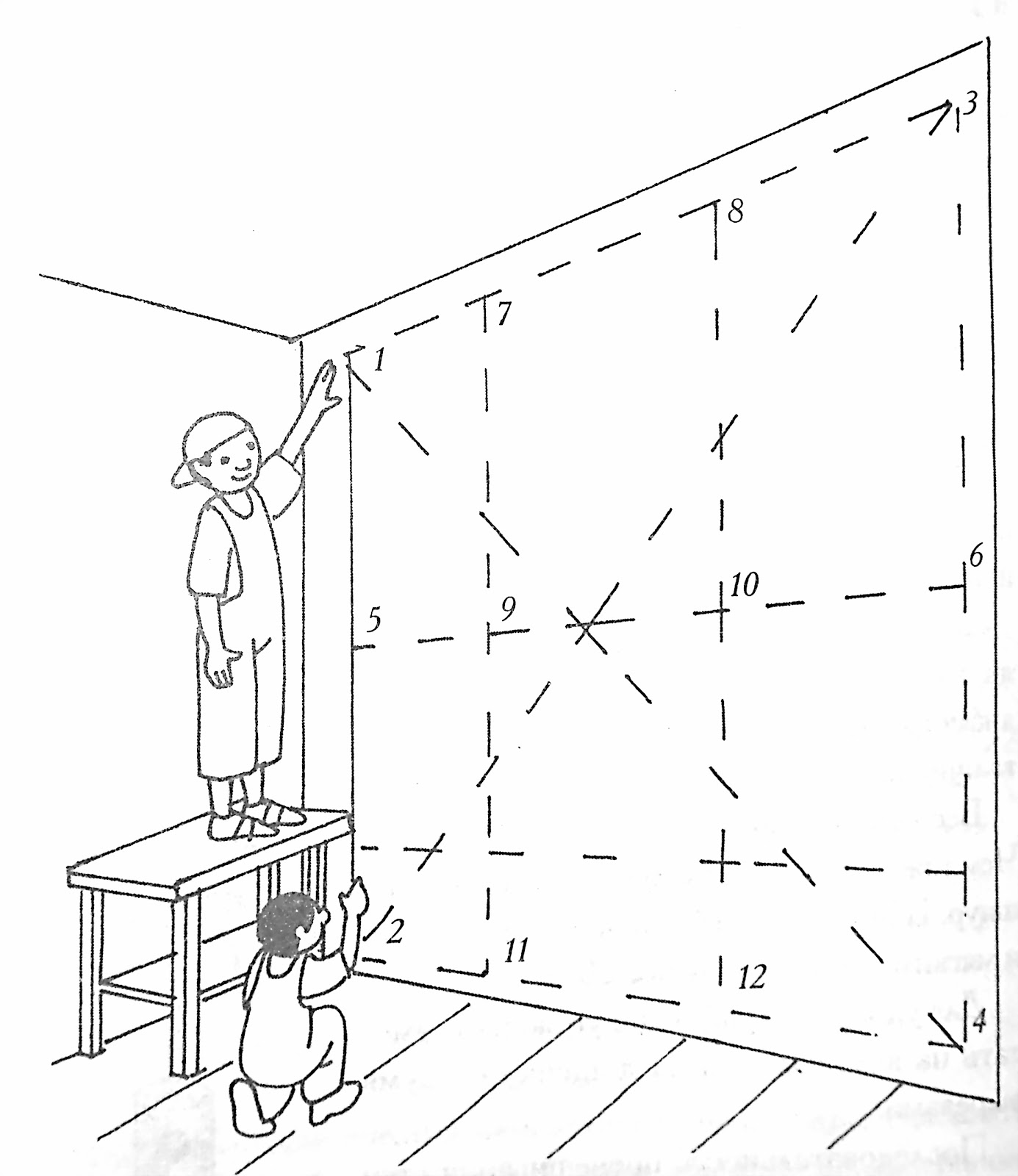

Hanging is carried out according to the scheme shown in the figure, while it is necessary to designate verticals and horizontals, the accuracy of which is checked using a level and a plumb line.

Denoting the levels, you need to remember the minimum layer. In the most protruding section of the wall, the level must be separated from the surface by the smallest permissible thickness of the plaster.

IN different places beacons are placed, which will serve as a guide during work. During plastering, the mortar is applied up to the height of the beacon, forming a flat surface. Actually, everything - now you can take on the calculator.

Algorithm for calculating the consumption of gypsum plaster per 1m2

First you need to determine the average thickness of the coating. The starting point of the calculation is the height of the marks, and the more of them are measured, the more accurate the result will be:

- We measure the height of several lighthouses;

- Add up the resulting numbers;

- We divide the sum by the number of beacons.

The resulting number is the average thickness of the solution, which will level the plane. It's time to look at the packaging, where the manufacturer probably wrote how much dry mix it would take to plaster 1 m² with a layer of 1 cm. This figure must be multiplied by the average layer thickness obtained by us as a result of torment with levels, plumb lines and lighthouses. The resulting value is the standard that plaster has gypsum consumption per m2 for a particular wall.

A calculation based on the data of one wall cannot be taken as the basis for the entire room, since the quality of the masonry can vary significantly even within the room.

The case is small - it remains to multiply the expense we received per square by the area to be processed. Just in case, let's recall the school curriculum in mathematics, from which it follows that the area of \u200b\u200ba rectangle is the length times the width (in our case, the height of the wall). Multiplying the surface area and consumption per square meter, we obtain the required total weight of the dry mix.

After spending a couple of minutes in a search engine, we find out the possible packaging of the manufacturer, and we divide the amount of the mixture we need by the volume of one bag, getting the number of packages to be bought. The calculation is over, the volume is known, you can go to the hardware store.

Consumption of gypsum plaster rotband per 1m2

For clarity, let's try to determine the amount of Knauf Rotband plaster required for a hypothetical wall. The manufacturer claims that this building material will require 10 kg / m² per 1 cm layer. Let's say that a wall 4 m long and 3 m high, evenly littered by 5 cm, is to be leveled. After hanging the walls, 5 marks were obtained, 1 cm high, 2 cm, 3 cm, 4 cm high and 5cm.

- The total height of the beacons is 1+2+3+4+5=15 cm;

- Average mortar thickness 15:5=3 cm;

- Consumption per 1m² 3х10=30 kg/m²;

- Wall area 3x4 \u003d 12 m²;

- The required amount of the mixture is 30x12 = 360 kg.

In the case of our hypothetical wall, the plaster plaster knauf rotband (30 kg) has a flow rate that allows you to process 1 square meter with each package. The German manufacturer packs its products in 30 kg bags, which means we need 360:30 = 12 bags of the mixture. The actual costs are usually higher than the theoretical costs, so it is worth buying an additional 5 or 10 kg package.

Standard consumption of plaster of different brands

Gypsum mixtures from different manufacturers have different flow rates, but in general, the algorithm of mathematical operations is absolutely the same. Below is the consumption indicated on the packages of gypsum plaster per 1 m2 of manufacturers Volma, Perfecta, Yunis, Bergauf, etc.:

- Volma gypsum plaster - consumption per 1m2 will be 8.5 kg;

- Perfekta promises for its products a consumption of 8 kg/m² at a thickness of 10 mm;

- Stone flower for plaster Agate claims 8-9 kg per square, depending on the method of application;

- The manufacturer UNIS guarantees that for a layer of 1 cm per square meter, 8.5-9 kg will be enough;

- gypsum domestic manufacturer Bergauf will need 11-13kg when applied 1 cm thick;

- Plaster gypsum rotband - consumption with a layer of 1 cm will be 10 kg;

- The Russian company IVSIL promises that 9-11 kg will be enough to cover a square meter of surface with a 1-centimeter layer.

The information provided is enough to accurately calculate the need for building materials and save yourself from the worries associated with repeated trips to the store.

In rooms for which this type of material is used, the microclimate is noticeably improved, since gypsum absorbs excess moisture from the air and gives it back when it dries. Thus, the humidity is always maintained at an optimal level.

Before buying certain building materials, you need to know how many of them will be required for a given area. For example, when choosing a coating, it is important to know the consumption of plaster per 1m2 for a particular base. Moreover, the consumption of decorative plaster will differ from the consumption of the main, leveling mixture. How to calculate the amount of plaster, and we will tell in this article. Plus a small bonus from OGODOM.RU - online calculator.

Content

- Calculator for calculating the consumption of plaster

- Factors affecting the consumption of the mixture for plaster

- Calculation of plaster

- Consumption of plaster depending on its type

1 Calculator for calculating the consumption of plaster

Specify the parameters of the wall for plaster, the brand of your dry mix and the consumption will be calculated automatically.

2 Factors affecting the consumption of the mixture for plaster

Two factors influence certain mixture costs - the type of plaster and the curvature of the walls. Depending on them, the required amount of material is determined.

- Type of plaster depends on the base (concrete, brick, wood, drywall). Therefore, the calculation is carried out for each specific case. Plus, the approximate consumption is prescribed on the packaging.

- Curvature of the walls or deviations vertically, horizontally shows the consumption of plaster per square meter. It is generally accepted that in new panel houses the deviation rate is 20–25 mm.

3 Calculation of plaster

The consumption of mortar for plaster is determined by the appropriate method. First you need to determine the average thickness of the proposed layer. For example, a 10m2 wall with a curvature deviation of 1 is to be finished; 3 and 5 cm (when hung on the surface at 3 points). Next, sum up 1+3+5=9. Then we divide by the total number of points 9:3=3.

As a result, the average layer of plaster is 3 centimeters. In this case, the maximum layer can be 5 cm, and the minimum is about 1 cm. On a note! If surface finishing is carried out along the beacons, then the layer thickness should be equal to the height of the beacons, that is, about 6 - 10 mm. Next, look at the packaging and read the manufacturer's recommendation.

For example, material consumption is carried out - or Rotband. The packaging says that to cover 1 m2 of the base with a layer of plaster of 10 mm, 8.5 kg of the composition is needed. The consumption of materials for plaster is calculated according to the following formula: 8.5 kg / cm * 3 cm = 25.5 kg per 1 m2 of base. For our entire surface of 10m2, we need 255kg (10m2 multiplied by 25.5kg/m2).

Each mixture is sold in bags with a total weight of 30 kg. Therefore, we calculate the number of bags required for finishing. For this, 255 kg: 30 kg = 8.5 bags. We round the figure to 9. The determination method does not present any difficulties, so there should be no question of how much plaster to use.

4 Plaster consumption depending on its type

Depending on the type of plaster, its consumption is determined. Consider the most popular types of mixtures and their estimated consumption.

- Decorative plaster requires 8 kg per 1 m2. However, much depends on the type of decorative mixture. Eg, Venetian plaster, the consumption of which will be about 70 to 200 g per 1 m2, requires lower costs.

- The gypsum mixture needs about 9 kg per 1 m2, where the layer should be about 10 mm.

- Rotbend requires 8.5 kg per 1 m2, while the layer thickness is 50 mm.

- The cement mixture requires 16–18 kg per 1 m2.

- Bark beetle plaster is spent at the rate of 2.5–3 kg per 1 m2.

- Vetonite requires about 1.5 kg per 1 m2.

In the event that you are confused in all these figures and the calculations cause you difficulties, you can use a typical online calculator. Such programs exist on many construction sites and allow you to determine the amount of material required with a minimum error.

However, they will make a good calculation if you have already decided on the type of mixture and know the area of \u200b\u200bthe intended surface to be treated, as well as the average layer thickness (these data are needed for a competent calculation). Enter numbers in the cells and get a specific total.

Video of mixing mortar

Video mixing decorative plaster

Photo of calculating the amount of plaster, ceramicartsdaily.org

Plaster consumption per 1m2: we plaster like professionals

If you decide to repair your apartment on your own, then in order to determine the financial costs, as well as the volume of material required for the purchase, among other things, you need to calculate the plaster consumption per 1m 2.

However, if you hire third-party specialists for repairs, knowledge general principles flow calculation building materials will also not be redundant. After all, knowing how to calculate the required amount of raw materials, you can control your financial costs much more accurately.

Plaster leveling is one of the most simple ways premises. For plastering, cement or lime mortars are traditionally used. At the same time, there are many specialized blends on the market today.

They allow not only to effectively level out all the irregularities of the walls, but also, using the texture of the plaster, to give the surfaces various decorative effects.

The specifics of the use of such material as plaster determines the fact that the beginning of work is quite difficult to say - how much plaster mixture will be needed to level the walls.

IN this material we will try to describe as clearly as possible the methodology by which the amount of plaster required for wall decoration is calculated.

To begin with, let's decide - the consumption of building material during plastering depends on it.

Factors affecting the consumption of plaster

So, what factors affect the consumption of plaster?

There are two main factors:

1. The curvature of the walls. How much the wall plane deviates from the vertical or horizontal depends on how much material is needed in order to level the walls with plaster. In new houses, the deviation can reach 20-25 mm.

Wall curvature check

But in the houses of the old housing stock, surprises are possible - both pleasant and unpleasant. In the house of construction, you can meet both ideal smooth walls, and walls with uneven curvature, installing beacons on which is a real torment.

2. Type of plaster. Depending on which mixture will be used, the plaster consumption rate differs.

Therefore, the calculation of the plaster is carried out for each specific situation, because it is enough to change the mixture - and the numbers will already be different.

So, after we have decided on the nuances, we can proceed directly to the method of calculating the required volume of plaster.

Method of calculation

Plaster consumption per 1 m2 is calculated as follows.

Namely:

- First, we calculate the required layer thickness.

For this:

- Thoroughly clean the wall that we plan to plaster.

- We hang the wall (i.e. set the level of beacons or beacon rails)

- In several places we define key points - in them we will measure the deviation of the wall from the plane. The more points, the more accurate the result will be.

- We measure deviations from the planned plane, summarize the deviations obtained and divide by the number of measured points.

Installation of beacons on the wall

Example of layer thickness calculation

In order for the method of calculating the thickness of the plaster layer to be clear, we will give an example.

Let's say it is necessary to plaster a wall with an area of 10m2, evenly heaped up by 50 mm (i.e. the maximum deviation is 5 cm).

- When hanging the wall at three points, we get deviations of 1cm, 3cm and 5cm.

- To summarize: 1 cm + 3 cm + 5 cm = 9 cm.

- We divide by the number of fixed points: 9 cm: 3 \u003d 3 cm.

- As we can see, in order to evenly plaster this wall, it is necessary to apply an average layer of plaster of 3 cm (1 cm is the thinnest layer, 5 cm is the maximum layer)

Note! When plastering walls along beacons, the minimum thickness of the plaster layer should be equal to 6 mm - the height of the plaster beacon.

Plaster beacon profile

So, we have determined the middle layer of plaster. Now is the time to take an interest in the manufacturer's recommendations: most often, the consumption of plaster per m 2, provided that the plaster is applied with a layer of 10 mm, is indicated on the package. So if you have purchased high-quality branded plaster, there should be no problems at this stage.

Let's continue with our example. Let's say that as a material for wall plastering, we choose a dry mix on a Knauf Rotband gypsum binder. indicates that plastering 1m 2 of the wall surface with a layer of 10mm will require 8.5 kg of dry mix.

We perform the calculation:

8.5 kg (consumption rate) * 3 cm (average thickness) = 25.5 kg.

As a result, we got the consumption of Knauf Rotband plaster mix for plastering a square meter of our wall, equal to 25.5 kg.

In order to plaster the entire wall with an area of 10 m 2, we need.

10 m 2 (wall area) * 25.5 kg (consumption per 1 m 2) = 255 kg.

This mix is packed up in bags on 30 kg. We calculate how many bags we need to purchase in order to plaster our wall.

255 kg (required amount of mix) : 30 kg (bag volume) = 8.5

We round up (since the actual consumption of the plaster mixture is always more than the calculated one) and we get 9 bags. It is this amount of dry mix that we need to purchase for plastering.

As you can see, this technique is quite simple and will help you determine the required amount of material for the purchase. And even if you do not plaster the wall yourself, but hire specialists, control has never harmed anyone!

Consumption rates of various types of plaster

As stated above, different types plasters have different consumption rates per 1m 2:

- For the simplest gypsum plaster, the consumption per 1 m 2 when applying a layer of 10 mm is 9 kg.

- For cement, the consumption of cement for plaster is 16-18 kg / m 2.

- Decorative plaster is consumed in the amount of about 8 kg / m 2, however, the exact consumption depends on the type of plaster.

- Consumption of plaster "Bark beetle" ( finishing material for facades) is 2.5-3 kg / m 2 (Please note! These figures are given for a layer of 1 mm)

Decorative plaster "Bark beetle"

However, if you find it difficult to calculate the required amount of material, you can use one of the online plaster consumption calculators. These programs allow you to calculate the required amount of material, provided that you have decided on the type of plaster, you know the area of \u200b\u200bthe walls to be processed and the estimated thickness of the plaster layer.

We hope that the technique given in this material will be useful to you, and when carrying out repairs, the question “How to calculate the amount of plaster?” won't confuse you!

Composition and consumption of mortar for plaster - builderclub

Hello!

I can only give you an average consumption, since the exact one depends on the humidity in the room (more or less than 60%), and on how even your walls are.

the consumption of the mixture per 1 m2 is about 0.02 m3.

So, if a cement-sand mortar is used in a ratio of 1: 3, then the consumption will be:

Cement is 0.005 m3, and sand is 0.015 m3.

Accordingly, for 10m2:

Cement is 0.05m3, and sand is 0.15m3.

If you will be plastering cement- lime mortar(proportion 1:1:6), then the consumption will be as follows:

per m2: cement-0.0025m3, lime paste-0.0025m3, sand-0.015m3.

Accordingly, for 10m2:

Cement - 0.025 m3, lime dough - 0.025 m3, sand - 0.15 m3.

Ask more!

Consumption of plaster per 1m2.

The easiest way to finish a room is to level the walls with plaster. To determine the funds spent and the volume required material, it is necessary to calculate the consumption of plaster per 1m2. However, to determine this amount, it is necessary to know the factors that affect the consumption of plaster, and there are only two of them:

1. Firstly, this is the curvature of the walls themselves, since the amount of material that will be needed to level the walls with plaster will depend on the vertical and horizontal deflection of the wall.

2. Secondly, this is the type of plaster, since the plaster consumption rate will depend on what type it will be used.

3. So, in order to calculate the required amount of plaster, it is necessary to calculate the required layer thickness, for which, on a thoroughly cleaned wall, beacons must be set according to the level, i.e. hang the wall, and then in several places determine the points at which it is necessary to measure the deviation of the wall. Next, you should take measurements from the plane, add up all the results and divide by the number of points. The result obtained will be an indicator of the average thickness of the plaster layer, which will allow you to plaster the entire wall evenly.

4. For example, it is necessary to plaster 10 square meters of a wall, which is evenly overwhelmed by 5 cm. At the established three points, the deviations are 1, 3 and 5 cm. Let's summarize these indicators (1 + 3 + 5 = 9) and divide by the number of points (9: 3=3), thus obtaining an average layer of plaster on the entire surface equal to 3 cm.

5. Next, you should determine the rate of plaster consumption per square meter. Typically, manufacturers on the packaging indicate this consumption with a layer of plaster of 10 mm. For example, plaster manufacturer Knauf Rotband indicates that 8.5 kg of dry mix will be needed to plaster 1 square meter with a layer thickness of 10 mm.

6. To determine the consumption of the above dry mix for plastering one square meter of wall, with a previously determined layer thickness of 3 cm, the indicated consumption rate (8.5 kg) should be multiplied by the average thickness (3 cm). The result of 25.5 kg will indicate the consumption of the mixture per 1 sq.m.

7. It is necessary to plaster a wall of 10 square meters with this plaster, and therefore the result obtained (25.5 kg.) Should be multiplied by the wall area (10 sq.m.). The result (255 kg.) will indicate the required amount of plaster for the entire required wall area.

8. To determine the number of bags of mixture, given result(255 kg) divided by the volume of one bag of mixture (usually 30 kg). It turns out 8.5 bags. This figure should be rounded up (9 bags) because the actual mixture consumption is usually greater than the calculated consumption. That is how many bags of dry mix you need to purchase for plastering 10 square meters of the wall.

9. At the same time, different types of plaster have different consumption rates per square meter. So, for example, the consumption of gypsum plaster, with a layer thickness of 10 mm, is 9 kg. For cement, the consumption of this material will be 17 kg per square meter, and decorative plaster will be enough for 8 kg. The consumption of bark beetle plaster, with a layer thickness of 1 mm, is 3 kg per square meter, and one and a half kilograms of vetonite will be enough.

Table of material costs

The consumption of materials (excluding losses) for the construction of 1m2 of the surface of a brick wall with a thickness of a quarter of a brick is:

cement (with mortar grade M-100) - 5 kg;

cement (with mortar grade M-75) - 4 kg;

cement (with mortar grade M-50) - 2.5 kg.

For 1m3 M 150 you will need: 220 kg of cement, 0.6 m3 of sand, 0.8 m3 of crushed stone.

For 1m3 M 200 concrete you will need: 280 kg of cement, 0.5 m3 of sand, 0.8 m3 of crushed stone.

For 1m3 M 250 concrete you will need: 330 kg of cement, 0.5 m3 of sand, 0.8 m3 of crushed stone.

For 1m3 M 300 concrete you will need: 380 kg of cement, 0.5 m3 of sand, 0.8 m3 of crushed stone.

Clay-sand mortar is a ratio of 1: 3, where one part of clay mortar and three parts of vermiculite. The resulting solution is poured with a layer of up to 50 mm

To make a layer of clay-sand mortar for warm screed or the construction of walls even warmer, you need to mix the clay-sand mortar in a ratio of 1: 1 with sawdust or floor (fine chopped straw). The prepared solution is poured with a layer 20-30 cm thick.

In order to create such a solution, which is mainly used for warming floors and ceilings of baths, you need to mix 1 part of the usual cement mortar(or ready concrete mortar) and 3 pieces of foam chips

Size 200x300x600 - 27 blocks in 1m3

Size 200(188)x200(188)x400 - 62 blocks per 1 m3

Consumption - 1-1.5 buckets of solution per 1m2. Instead of an expensive plasticizer, 2 caps of cheap shampoo (for plasticity) per batch 1/4, 1l. jar of black pigment, and in order to avoid efflorescence 200g. 9% solution of vinegar.

Penekrit 150-200 grams per seam 25x25 mm per 1 linear meter of strobe

Penetron (for 2 layers according to technology) from 0.8 kg - 1.1 kg per 1 m2, depending on the looseness and unevenness of the surface

Table of costs Consumption of cement-sand mortar per masonry: For 1 m2 of brickwork with a masonry thickness of 1 brick, the amount of mortar approaches 75 liters from the consumption per 1 m2. If the laying of a brick wall is 1.5 bricks thick, then the amount of mortar will correspond to a figure of 115 liters. Proportions of cement mortar: In order to prepare building mixture, you need: 1 part binder (cement) and 4 parts aggregate. Proportions of the plaster mixture: You will need 1 part of the binder (cement) and 3 parts of the aggregate. Consumption of cement mortar per brick: According to consumption rates 400 pcs. bricks (more precisely 404) - 1 m3 of masonry. The consumption rate of the solution per 1 m3 is 0.23 m3 (in practice, 0.25 is accepted). How to calculate the consumption of sand concrete M - 300 per screed? Approximate sand concrete mixture 1.7-1.75 kg / cubic dm Per 1 m / 2 with a thickness of 1 cm = 18-20 kg. mixture (sand concrete M300). Glue consumption: The consumption of tile per 1 m2 of laid is 10 kg. dry mix at layer thickness ready solution 10 mm. Adhesive consumption for foam concrete blocks and gas silicate blocks: Adhesive consumption for foam concrete per 1 m3 of laid foam concrete masonry is 40 kg. dry mix. Consumption of self-leveling floors: Consumption of self-leveling floors per 1 m2 of ready mortar is 6 kg. dry mix, with a recommended layer thickness of 5 mm. Plaster consumption: Plaster consumption per 1 m2 of the finished mortar is 10 kg. dry mix, with a recommended layer thickness of 10 mm. Consumption of putty: Consumption per 1 m2 of the finished solution is 0.9-1.0 kg. mixtures. Grout consumption (tile joints): Grout consumption per 1 m2 of laid tiles is 120 g, with a recommended joint thickness of 2 mm. Consumption of the universal mixture M-150: The consumption of the universal mixture M-150 per 1 m3 of the finished solution is 1450 kg. dry mix. Consumption of masonry mixture M-200: The consumption of masonry mixture M-200 per 1 m3 of masonry is 350 kg. dry masonry mix. Consumption waterproofing material(penetrating layer): Waterproofing consumption per 1 m2 of surface will require 700 gr. dry mixture diluted to the state of sludge for application with a brush (roller). Paint consumption: Paint consumption per 1 m2 of walls or ceilings at the first application on a primed flat surface is 0.3 liters, the second layer upon correct application is 0.2 liters per 1 m2. Consumption of polyurethane floors: The consumption of a polyurethane self-leveling floor when applied to a dedusting primer is 1.5 kg per 1 m2 of concrete floor surface, with a thickness of 1 mm. The amount of cement per masonry: To prepare 1 m3 of cement mortar, 8 bags of cement, 50 kg each, are needed. and kneaded in a ratio of 1:4, where one part of the sand is also equal to 50 kg. How much cement, sand, gravel in 1m3 of concrete (how to prepare - proportions): Clay-sand mortar. How to prepare: The proportion of concrete and foam chips: How many blocks in 1 m3 of masonry? (more details in the table - see below) Secrets of brick or block facing masonry, masonry mortar+ black seam: Consumption of penetrating waterproofing penekrit and penetron:

Brick size Without mortar joints. pieces with mortar joints. PC

Single512394

One and a half378302

Double242200

Single6151

One and a half4539

Double3026

Single128102

One and a half9578

Double6052

Single189153

One and a half140117

Double9078

Single256204

One and a half190156

Double120104

Single317255

One and a half235195

Double150130

How many bricks (bricks) in 1 m2 or 1 m3 of wall masonry (in the wall) Unit of measurement 1 cubic meter. masonry 1 sq.m. masonry in 0.5 bricks (masonry thickness 12 cm) 1 sq.m. masonry in 1 brick (masonry thickness 25 cm) 1 sq.m. masonry in 1.5 bricks (masonry thickness 38 cm) 1 sq.m. masonry in 2 bricks (masonry thickness 51 cm) 1 sq.m. masonry in 2.5 bricks (masonry thickness 64 cm)

How many blocks (block) in 1 m2 or 1 m3 of wall masonry (in the wall) Size 600x300x200 500x300x188 610x288x200

Joint width (mm)

Таблица расхода затирки (кг/м2) Размер плитки (мм) 1 Расход затирочной смеси (кг/кв.м) 20х20х3 50х50х4 50х100х10 50х200х10 50х300х10 100х100х6 100х200х8 125х250х8 150х150х6 200х200х8 200х200х12 200х200х14 200х250х8 200х300х8 250х300х8 250х330х8 250х1300х10 300х300х8 300х300х12 300х300х14 330х330х8 330х600х8 300х600х10 400х400х10 450х450х10 500х800х10 600x600x10 600x1200x11

Rotband plaster is a special gypsum mixture For interior decoration walls and ceiling. It is suitable for use on wall surfaces made of building materials such as brick and aerated concrete blocks, as well as when finishing even concrete surfaces walls and ceilings in apartments multi-storey buildings.

The consumption of the dry mixture will depend primarily on the thickness of the layer. This indicator has an optimal value, which is obtained on the basis of many years of practical experience in the use of Rotband by various construction teams and is 1 cm or 10 mm. If you need to apply a significant amount of plaster, using special beacons for this and a large amount of the finished mixture, then using only Rotband for this can be an unreasonably costly undertaking.

Wall plastering on lighthouses is used in cases where there are clearly visible irregularities on the walls, which are more difficult to remove than to hide them behind a layer of plaster. This also includes the situation with uneven walls in an apartment or house: make them completely flat vertical surface along the entire length it is possible only with a large layer of plaster or laying drywall sheets.

It would be appropriate to use the Rotband mixture when plastering generally even block or brick masonry, in which you just need to fill in the gaps in the seams between building blocks. For these purposes, a layer thickness of 10 mm will be sufficient, for which there is a standard dry mix consumption indicator. Consumption of Rotband plaster per 1 m² is 8.5 kg with a layer thickness of 1 cm.

Since the mixture is sold in dry form, the consumption is indicated specifically for the mass of dry powder. As for the mixture ready for application to the wall, it is made by mixing Rotband with water in a ratio of 1 to 0.6, that is, 6 liters of water are consumed per 10 kg of dry powder. Usually this gypsum plaster is sold in bags of 30 kg, so that one bag uses about 18 liters of water and the surface area that can be plastered is approximately 3.5 m². The price of Rotband in hardware stores is approximately 370 rubles per bag weighing 30 kg.

Consumption Calculator

The number of kilograms, depending on the surface area of the wall section:

Result: kg

We consider the area of \u200b\u200bthe wall:

Result: m²

Quantity of 30 kg bags for finishing a certain wall area:

Result: piece

The cost of bags at the rate of 370 rubles per piece:

Result: rub

How to reduce consumption?

If the layer thickness is planned to be more than 1 cm, but you want to finish the wall with Rotband, then you can simply make a two-layer finish. Apply the first layer of plaster cement-sand mixture, and after its complete drying (at least 30 days), cover the surface with a thin layer of gypsum plaster. This combination will make the surface of the walls strong and durable, in the future any even heavy structures can be safely mounted on dowels and not be afraid that the finishing layer will begin to crumble and crumble.

As an alternative to the classic solution of water and gypsum plaster, this mixture can be add sand in such quantity that by weight it correlates with Rotband as 1 to 1. Accordingly, the amount of water here will need to be doubled and the resulting ratio of ingredients will be 10 kg of Rotband, 10 kg of sand and 12 liters of water.

A feature of such a solution will be the need to make more efforts when working with the composition. The application process will be difficult to a large extent, since to obtain a good flat surface similar in quality to the surface where Rotband not diluted with sand is used, it will take significantly large quantity time and effort.

Where can you use Rotband?

Now for plastering walls from various materials, there are a large number of alternative mixtures, which have a wide range both in price and quality. At the same time, specialized compositions are produced, the use of which is recommended specifically for a specific type of concrete blocks, or a type of brick.

All of them basically have two fundamentally different main ingredients - cement and gypsum. Cement plasters it is recommended to use in rooms where during operation a constantly high level of air humidity and noticeable temperature changes are expected. Most often, this refers to a bathroom in an apartment or a garage or an indoor pool in a private house.

Gypsum mixtures are not frost-resistant and sensitive to high humidity. Rotband is not suitable for finishing walls for painting, as it shrinks during the drying process. To prepare the ideal surface that walls require for painting, at least one more layer of universal gypsum putty, Knauf type Fugen (Fugenfüller). And ideally add a third finishing layer putty Vetonit, which does not shrink at all.

The time for complete drying of the walls plastered with gypsum Rotband is from 2 to 7 days, depending on temperature, air humidity and ventilation intensity of the room. On a dry summer day, complete drying occurs in two days, it can be determined by the color of the surface, which brightens as moisture evaporates from it.

Be sure to use a special primer to treat the surface of the walls before applying the plaster. Without their use, the likelihood that the finishing layer will actively crumble when exposed to a drill, when it becomes necessary to hang a shelf or some other heavy structure on the wall, increases significantly. The average primer consumption is approximately 100 grams per 1 m².