Basement siding: Everything you need to know about finishing your home with basement siding. Types of siding for exterior decoration What is cheaper siding or facade panels

Everyone tries to design their house or other building in such a way that it pleases the eye. This can be done using a wide variety of various materials. The choice of some is driven by desire, while others are guided by what the budget allows. In both cases, it makes sense to consider the types of siding for exterior finish. The article will allow you to review each of them and choose exactly what will be the best value for money.

What is special about siding

The name "siding", which has become very firmly established in our everyday life, is actually borrowed. It came from in English from the word side, which translates as "side". In principle, this is logical, given that it is mounted on the wall. It is designed to provide two functions at once:

- decorative;

- protective.

Regarding the first siding boasts a wide selection color solutions, as well as a variety of structural types. Siding is indeed an excellent protective material that can protect the insulation and the walls themselves from unpleasant weather conditions. Most types of siding perfectly resist hail, heavy winds and other physical impacts.

Siding is in many ways similar to lining for exterior finish. It consists of individual sheets that are mounted in general design. Siding is not a completely airtight material. Otherwise, the walls under it would fall into disrepair. That is why special ventilation holes, which are necessary for the weathering of moisture and condensate.

Some types of siding can last up to 50 years for their owner. This good investment money in finishing, which will not require much intervention. Most types of siding are very easy to maintain.

They are easy to clean with a washcloth and detergent or simply with a hose. The beginning of the history of the existence of siding is rooted in Switzerland. The first mention of the material used to sheathe the walls in this way appears more than two centuries ago. During this time, the method went through a series of modifications and transformations, becoming what we know it today.

Material types

Siding for exterior wall decoration is made from almost all materials that are used in construction today. To make a choice, it makes sense to consider the advantages and disadvantages of each of the products, as well as see them in the photo.

Vinyl

To be more precise, vinyl siding is actually made from polyvinyl chloride or PVC. This material has a large number of positive aspects:

- flexibility;

- burnout resistance;

- crack resistance;

- light weight;

- ease of installation;

- high environmental friendliness;

- large variation in operating temperatures;

- not subject to corrosion.

PVC siding itself has good flexibility. This provides some freedom during installation work. This type of siding is available in a large number of colors. During the manufacturing process of the panels, which are later used to decorate the house, a pigment dye is added, so it is easy to choose exactly what will best suit the overall exterior of the yard.

PVC siding perfectly tolerates the effects of various acids, so in areas where there are large factories, its service life does not decrease. Siding sheets of this type can be fastened both with vertical and horizontal positioning.

Another indisputable advantage of this particular type of siding is environmental friendliness. The manufacturing process does not use harmful solvents and other substances, so there are no harmful emissions even when heated. The operating temperature of such panels ranges from 50 degrees below zero to 50 degrees above zero. When installing PVC siding, wall cladding with insulation for external use is required. In this case, it will be possible to achieve the desired effect. Of the minuses of the material, one can single out the relative resistance to physical influences. It is also almost impossible to replace only one bar without dismantling the neighboring ones.

Aluminum

Another type of exterior wall decoration is metal siding. It can be made directly from metal or aluminum sheets. Aluminum metal siding is durable and relatively light. Its weight, of course, is greater than that of the PVC version, but relatively less than that of other types. Often this type of exterior decoration is used for multi-storey buildings where there can be a large wind and weight load. Installation of metal siding is also quite simple, so all work takes a short period of time. A significant disadvantage of this type of exterior finish is its cost. But it is more than covered by pluses, which more than outweigh.

Aluminum is an inert material, it does not corrode, so it will last a very long time. Such siding does not burn or melt, so even in difficult situations it will not pose a threat to human life. Aluminum perfectly tolerates sudden and significant temperature changes without deformation and damage. The color of the siding can be chosen by the owner.

It can be changed without any consequences or use the one that comes from the factory. There are options for sheets with wood embossing. An ignorant person without a tactile test can easily confuse it with a wooden one. Maintenance of aluminum finishing material is not difficult. Finishing material under the tree is easy to clean with a regular rag or pressure from a hose.

Metal

Metal siding in its classic version is made of galvanized sheets. At the same time, it can also be decorated in appearance like a tree, because solid smooth sheets of material do not look so beautiful. For protection, the outer side of the finishing material is coated with a polymer composition. It is able to mitigate various physical impacts and prevent corrosion. Each sheet of this type of material has a lock structure. This suggests that there is no need for additional waste for fastening material. Everything is assembled clearly and quickly. Metal products have the same positive aspects as aluminum sheets of exterior trim.

Note! Subject to the manufacturer's recommendations during installation, you can count on the service life of this type of material in 50 years.

Maintenance includes regular inspection of the entire surface and the timely elimination of cracks and scratches that may occur due to physical influences or temperature fluctuations.

Ceramic

Ceramic siding has not yet become widespread, because it is a novelty, but it has all the prerequisites to become one of the most popular finishing materials. It has one of the best value for money. Sheets are made quite high quality, and the cost is relatively low. The basis of this type of finish is clay. This means that the end product is environmentally friendly. Typically, this finish is used by those people who are very attentive to their health or are allergic to certain materials and odors.

The appearance of ceramic cladding can also be made to look like wood. It is difficult to point to a building where such decoration would look out of place. If you ennoble a country house with such material, then it will look like one of the best, if not the best among the neighbors. An example of such a finish can be seen in the photo below.

cement

Cement is widely used not only in construction, but also in finishing tasks. He managed to get to the siding. By itself, cement siding is quite fragile. If handled carelessly, it can easily burst or crack. To compensate for this shortcoming, the design of the sheets was supplemented with cellulose fiber. It provides rigidity and uniformity of the structure.

A different pattern can be applied to the front side of such siding. Most often it is made under a tree. The price of this type of siding can be quite high. But it is compensated by a long service life, a presentable appearance and fire safety. Installation of siding sheets occurs by analogy with other types.

Wood

This type of siding is one of the most expensive. This is due to the high cost of the wood itself. It is its presence that is an undeniable advantage. To a greater extent, such siding is known as a block house. It is part of a round log. There are also options in the form of a board or a false beam. Such siding can be made from solid wood or glued fibers. Its appearance is the most attractive, but otherwise the material has big amount cons. It requires constant handling and care.

Wood is sensitive to moisture and may swell or warp. The period during which such siding will please with a beautiful appearance is much less than that of analogues. If a fire occurs, the plane will catch fire very quickly and become unusable. Another problem will be various animals and insects that can spoil the wood.

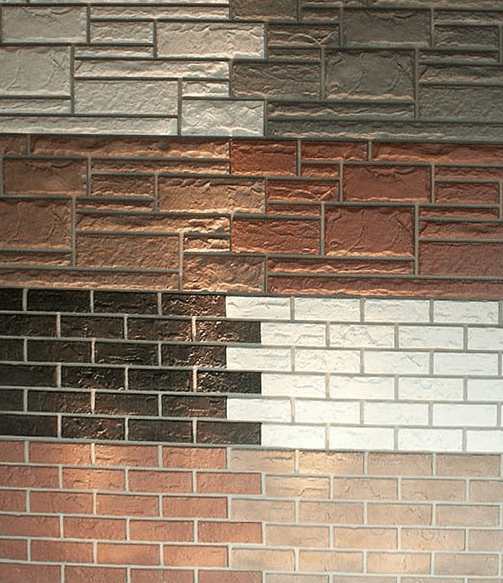

Plinth siding

No wonder this type of siding is placed in a separate subcategory. It is used for one purpose - to protect the basement from damage and excessive absorption of moisture. In order to achieve the desired effect, you will need to use siding with a thickness of at least 3 mm. Basement siding sheets are smaller in size compared to wall siding. This is done for more convenient installation and passage of difficult areas. Also, basement siding sheets are heavy. This type of finish can have a different color that imitates stone or brick. Often, such siding can be used in tandem with other finishing materials, such as facing bricks. The manufacturing process of this finishing material involves the use of durable components. At the same time, the decoration will please the owner as much as the house itself. At the same time, the sheets are resistant not only to weather conditions, but also to physical influences, such as impacts, which often occur at this level. A video of the installation of such siding can be viewed below.

Note! It is important to remember that the use of basement siding is possible only if the top point of the surface being designed is at a minimum level of 15 cm from the ground.

Conclusion

When buying any type of siding, be sure to pay attention to the conditions in which it was stored. Consider the thickness of one sheet, as well as the compliance of the parameters with GOST standards. The packaging must be intact, without cuts or breaks. Better buy facing material in large centers where it is frequently updated.

The article was prepared with the participation of Holzplast specialists

A hinged ventilated facade with a cladding screen made of polymer siding is one of the most popular methods of exterior decoration in the private sector. This is largely facilitated by both the universality of the system, which provides a wide scope of application, and its availability. Manufacturers today offer a large assortment shapes and textures in a wide range of colors, as well as a lot of decorative elements. Due to which, through siding, it is really possible to transform almost any facade without wet processes.

Like any material, siding has certain characteristics that directly affect the attractiveness and durability of the facade. With the help of Holzplast specialists, we will dwell in more detail on vinyl siding, its features and nuances of operation.

- About siding.

- Popular types of cladding.

- Nuances of installation and operation.

About siding

By by and large siding is almost any exterior cladding, if translated from the original language, but in the middle of the last century, the Americans called polymer decorative panels, imitating natural wood, developed at one of the factories. Initially, siding was made only from polyvinyl chloride (PVC), later metal and fiber cement appeared. But it was PVC siding, abbreviated as vinyl, that was and remains the most popular facing material.

The brick facade gives the house a solid and expensive appearance. To achieve this effect, you can use facing brick or siding. Despite the external similarity, these are two completely different materials with their own advantages and disadvantages.

Facing brick: the price justifies the quality

The facing brick is intended for external finishing of facades of buildings. It protects the walls from moisture, high and low temperatures, as well as mechanical damage. This is a very durable and reliable material.

Advantages of facing bricks

environmental safety - facing bricks are made from natural materials;

frost resistance;

resistance to temperature extremes and high humidity;

strength and durability;

respectable appearance.

However, facing brick creates a high load on the foundation and load-bearing structures. Therefore, if you did not foresee the strengthening of the load-bearing structures of the house in advance, you will have to refuse to clad the facade with bricks.

Facing bricks have several other disadvantages.

the complexity and duration of the laying process (in order for the brick to lie flat and not fall off, you will have to use the services of a professional stacker);

high cost of material and its installation.

Facade panels: is it worth overpaying?

Brick-like plastic siding (front panels) repeats the color and texture of the brick. From a distance and from a photograph, it is almost impossible to distinguish between these two finishing materials.

Front panels are made of polypropylene. They are designed for lining the plinth and have increased resistance to mechanical damage and the impact of atmospheric phenomena - snow, rain, temperature changes, etc. Due to their low weight, facade panels can be faced with almost any house or part of it.

In terms of strength and durability, facade panels are practically not inferior to natural stone, but at the same time they are much more affordable. Therefore, in most cases, when there is a choice: siding or facing bricks, they prefer what is cheaper.

Brick siding is a ventilated facade. Air circulates freely through the gap between the wall of the building and the panels, preventing water stagnation, the formation of fungi, mold and moss.

Facade panels have the following advantages

a light weight;

quick and easy installation;

protection of the building wall from moisture, mold and rot;

unattractive to fungi and moss;

affordable cost.

The disadvantages of facade panels include the fact that this is not a natural brick. And upon closer examination (at a distance of less than 1 meter), it is noticeable. In addition, facade panels have less strength and resistance to mechanical damage.

Siding or facing brick: comparison

Both facing materials have sufficient durability (at least 30 years), strength and frost resistance.

Facing brick is much heavier than siding: one brick weighs from 1 to 2.3 kg. Therefore, its use is limited. Siding - lightweight material, it can be applied to any building.

Brick laying is a long and laborious process. Just imagine: one brick has dimensions of 260 x 120 x 65 mm. The width of one siding panel ranges from 445-470 mm, length - 1130-1217 mm, thickness - 16-23 mm. This fact alone suggests that laying bricks will take significantly longer. In addition, this process is difficult and requires professional skills. The cost of laying can significantly exceed the price of the brick itself.

Installing front panels is much easier. With strict observance of the manufacturer's instructions, even a beginner can handle it. This does not require special devices, tools and skills.

Facade panels do not lose their strength after 60 freeze/thaw cycles. For bricks, this indicator depends on the quality of the material and can vary between 50-100 cycles.

Moss and mold like to settle on the surface of natural brick in wet and shady corners. On plastic panels they don't appear.

Full list distinctive features bricks and facade panels is shown in the table below.

Which is better: siding or brick?

| Characteristic | Stone and brick siding (facade panels) | Brick | Suitable for any foundation | High, before laying it is necessary to calculate whether it is possible to use such a facade |

| Frost resistance | 60 cycles | 50-100 cycles |

| Moisture resistance | Waterproof | Waterproof |

| Impact and deformation resistance | Plastic material, can take the original shape | Very strong material, but chips can form |

| Mounting speed | High | Low |

| Durability | Up to 30 years and more | 50 years or more |

So, what to choose, siding or brick, depends on your preference and on your willingness to pay for natural material. One question remains: is it worth it? Facing brick - natural and beautiful facade material. But given the complexity and high cost its laying, in some cases it is more expedient to use facade panels.

Siding has grown in popularity in recent years. Previously, 25-30 years ago, the inhabitants of our country could see beautiful and bright multi-colored houses, only leafing through magazines that leaked into our reality from under the Iron Curtain. Now siding can already be seen in our domestic magazines, and in hardware stores, and on real houses. And if you wish, you can see this wonderful material on the walls of your house.

Suffering from the unavailability of this material for a short time replaced by the complexity of the choice, as the market offers siding from a variety of materials, colors, textures, fastening systems and prices. And from the whole ocean of questions that a person may have when choosing, we decided to consider only one: which siding is better - acrylic or vinyl? It is possible that having decided on this, the potential buyer will have at least two times fewer questions.

Increased attention to the facing of the house with siding is not only a tribute to fashion, but only in part. And this facing material gained popularity due to a combination of its characteristics and qualities. What arguments does siding have in its favor?

- Of course, people who buy siding, first of all, want to improve the appearance of their homes. Moreover, both new and already quite "old". For cladding with siding, it is not necessary to level the walls, all irregularities are compensated by the frame and crate. Sometimes you can watch how an unsightly house with all the signs of a noble old age suddenly turns into a “candy house” in a few days. Let it only bright wrapper, but still the appearance of the house greatly affects the mood of the owners of the house and the choice of potential buyers of suburban real estate.

- Siding protects the walls of the house from external adverse influences. This is especially true for wooden houses. Under the siding, the walls are not threatened by either wind or precipitation, which can contain very aggressive elements in industrial areas. chemical compounds bad for building materials.

- Siding itself is able to withstand the effects of natural factors. He is not afraid of precipitation, winds too, but subject to the installation technology. The only drawbacks are the susceptibility to ultraviolet rays included in the solar spectrum and the fragility of polymer panels in severe frosts. The first disadvantage is now almost overcome, thanks to the use of new materials and technologies. The second minus is also partially overcome by introducing special modifiers into the composition of the panels, but no one has yet canceled the careful attitude that should apply to any finish.

- Siding allows you to hide a lot of interesting and necessary things underneath. First of all, it concerns heaters. To make the cladding of a house out of siding and at the same time not to place a heater under it is just a crime. In addition to insulation, vapor-permeable moisture-proof membranes are recommended for use, which protect against direct exposure to water, but allow water vapor to pass through. The walls of the house will not be sealed, but will be able to "breathe", but on condition that basalt mineral wool is used as a heater.

- Facing from siding allows you to make a ventilated facade near the house. This approach significantly increases the service life of the insulation, improves its thermal insulation qualities, and allows you to quickly and without hassle get rid of excess moisture that has appeared on the walls.

- The use of siding in the cladding allows you to get away from the traditional troublesome and wet plastering processes. The speed of finishing increases significantly, costs decrease, and ease of installation allows you to do everything yourself.

- The service life of siding cladding allows you to do it once and for many years or until you get tired of it. According to manufacturers, the service life of some types of siding is at least 50 years.

- Siding is very easy to care for. Most often, it can simply be washed with a stream of water without the use of any special detergents.

- Siding has an affordable price, is presented in the widest range, installation technologies are available both in terms of the availability of the necessary information, and in the simplicity of self-execution without expensive special tools.

Enough arguments have been made in favor of siding to explain its widespread use. Undoubtedly, this wonderful material will continue to be widely used in individual housing construction, and in the middle, most massive class. It is clear that elite suburban housing will continue to use both facing bricks and clinker tiles for decoration, but for most residents of the post-Soviet space, siding will be just a salvation.

How to compare acrylic and vinyl siding

Let's imagine ourselves in the place of a buyer who came to a huge store, where siding is presented from all possible materials, any colors, any manufacturer and different price categories. And it is necessary to choose only one from all the variety. This task is, of course, not an easy one. Therefore, it is necessary to break it down into several simple ones. And each such simple task is, at its core, a question that buyers ask when choosing a siding.

- Buyers, first of all, are interested in the appearance of the siding, and only then all its characteristics. With the current wide selection, this is not a problem, since both vinyl and acrylic siding can be selected in any color and texture.

- The second issue is durability. Always and everywhere they ask the question of how long the siding will retain its “fresh” look, as at the time of purchase, and only then they are interested in the durability of the material itself.

- Often they are interested, especially residents of the northern regions, how siding perceives temperature changes: does it become too fragile in very coldy. Residents of the south are interested in the behavior of siding in extreme heat - whether it will “float” and whether it will emit unpleasant odors, which, in combination, are often harmful to health.

- If the buyer is going to install the siding on his own, then the installation technology is of interest. There are no questions about this, since sellers are willing to provide information. Yes, and on the Internet you can always find both official information from manufacturers, and personal experience, with whom they are willingly shared on forums on construction and repair.

- The level of environmental literacy and consciousness of the population of our country is growing and this cannot but rejoice. According to some sellers, there are buyers who ask not only about the harm to their own health, but also about how siding affects the environment.

- Of course, you are always interested in what brand the siding is produced under and in what country, since this is also of great importance.

- The price of siding is always of interest, but what is strange is that this question is almost never in the first place if people buy just for themselves.

Characteristics of vinyl and acrylic. How do they affect the quality of siding

In many ways performance characteristics siding determines the material of its foundation. In our case, vinyl and acrylic. However, it should immediately be said that good siding has not been made uniform in composition for a long time by monoextrusion, that is, pushing the molten mass through an extruder. Modern technologies allow you to make siding two-layer: the lower layer provides mechanical strength, and the upper one carries both protective and decorative function. Therefore, there is equipment that makes it possible to obtain two-layer sheets bonded at the molecular level from the melts of two components. This process is called co-extrusion. And this technology is used to get the vast majority of siding.

Considering the multi-layered structure of the siding and the presence in its composition of many modifiers, dyes, stabilizers and other additives, it can be stated that one hundred percent "racial" purity of vinyl and acrylic siding does not exist in principle. We can only say that these materials form its basis and determine its properties.

Polyvinyl chloride (PVC, vinyl,PVC)

The most common is vinyl siding. It owes its name to its main component, which makes up more than 80% of its composition. This is nothing more than polyvinyl chloride (PVC) - one of the types of plastics that has found the widest application among its "brothers" in the class. The Russian name for this material is PVC, and in the rest of the world it is called PVC.

Polyvinyl chloride is a wonderful material and is the best suited for finishing. More than 60% of vinyl produced in the world is used specifically in construction - for the production of siding, finishing panels, window and door profiles, window sills and other products. Such a demand for polyvinyl chloride is easily explained, since with a relatively cheap process technological production, PVC has a number of good properties:

- PVC has high mechanical strength, wear resistance, rigidity. At the same time, all these qualities are combined with a small specific gravity(density), which is 1.35-1.43 g / cm³.

- Vinyl is weather resistant. All naturally occurring solvents, the main of which is water, have no effect on it. PVC does not "know" what corrosion and biological damage are.

- The temperature resistance of polyvinyl chloride is also on top. Pure, without any additives, PVC can be used for a long time at a temperature of 60°C. it begins to melt at a temperature of 150-200°C, and begins to burn only at 500°C. Moreover, after the source of high temperature disappears, the combustion immediately stops. In other words, PVC does not support combustion.

- PVC is a very good dielectric, and it is not for nothing that it is widely used for insulation in cable and wire products. The same property is very useful in finishing materials, the ability to conduct electric current is simply inappropriate here.

- Vinyl building materials compare favorably with their durability.

- PVC is very easy to process with a simple tool.

It is known that ideal materials do not exist, and PVC has weak spots that need to be taken into account:

- When PVC is heated to temperatures up to 100°C, it begins to decompose and release hydrogen chloride HCl, known to us as hydrochloric acid, into the surrounding air. This can lead to irritation of the upper respiratory tract and mucous membranes of the eyes. But under standard operating conditions, such a temperature can appear only in extraordinary cases.

- At low temperatures, PVC becomes more brittle, but almost all building materials have this unpleasant property. The main thing is that low temperature does not cause degradation of the material.

- The main disadvantage of vinyl is photodegradation when exposed to ultraviolet light. With prolonged exposure to direct sunlight, high-energy photons of ultraviolet light break down PVC molecules. This phenomenon is fought and quite successfully with the help of special additives. Which ones we will tell below.

In its pure form, polyvinyl chloride is almost never used. It is always "customized" under desired application by adding various ingredients. What is added to vinyl siding?

- First of all, this is actually polyvinyl chloride itself, which makes up about 80% in the finished siding. But he is different. It is best if only primary raw materials are used for production, but in reality this is far from the case. In the chemical industry, secondary raw materials are widely used, which are obtained by processing products that have already been in use. This noble mission contributes to the preservation of the environment, but does nothing to improve the quality of PVC siding. The best manufacturers add no more than 5% recycled PVC to their products and honestly report it, while some other unscrupulous manufacturers can “sin” with a large percentage of gray-back PVC (recycled PVC) and not tell the buyer anything about it. In appearance, this difference can not always be determined. Therefore, it is worth buying only siding from a good, honest manufacturer from no less good and honest sellers.

- Titanium dioxide is also the most common additive in vinyl siding. This compound is also called titanium white, and also as a food additive E171. It is added only to the top layer during the co-extrusion process and it serves to give stability to the top layer, to prevent destruction by UV rays. As a result, the color of the siding is less prone to fading. But titanium dioxide works only with light and soft tones of the siding color, more expensive chemical compounds are used on brighter and darker ones. The top layer contains no more than 10% titanium dioxide.

Titanium white or titanium dioxide - an indispensable additive in the top layer of light-colored siding

- Calcium carbonate - this compound is always used in the production of plastics, especially PVC. This component is introduced into the lower layer, and it is from 10 to 15% of its composition. It is a filler and in addition contributes to the uniform coloring of PVC throughout the volume.

- Butadiene is a compound found in PVC used in siding. Its content is no more than 1%, but even such a small proportion makes it possible to stabilize PVC, and most importantly, to increase its elasticity and wear resistance. To be precise and honest, butadiene is not included in its pure form, since it is a gas. Styrene-butadiene thermoplastics are used, which are added to polyvinyl chloride. The same compound is necessarily used for the production of high-quality synthetic rubbers and road bitumen, which retain their elasticity over a wide temperature range.

- Various modifiers that improve the impact resistance of the siding are also introduced into its composition. Their share is very small, but they significantly add strength properties. Specific chemical composition and the content of these modifiers are the know-how of manufacturing companies and, for obvious reasons, are not disclosed.

- To paint the siding in the desired colors, concentrated pigments are introduced into it, which should give desired color and shade, while still being resistant to fading from exposure to UV rays. Of course, their composition is also the intellectual property of the manufacturer and is not subject to publication.

- Good siding is never glossy. Therefore, in the process of its production, matting additives are always added to the top layer, which remove the original gloss.

- Antistatic additives are also required, since the properties of dielectrics are known to accumulate static electricity. Few people will be pleased to receive an electric discharge from the walls of their home.

Polyvinyl chloride siding dominates the market, primarily due to the fact that it began to be produced much earlier than the newer acrylic. This gain in time allowed vinyl siding to firmly establish itself as a leader. But its position becomes somewhat shaky, as a new material comes - acrylic siding.

Acrylic and its derivatives used for the production of siding

The concept of acrylic is very broad and includes a very large group of synthetic materials - both solid and liquid. For the first time, under the concept of acrylic, a fabric made of acrylic fiber appeared, and then various polymers began to appear. This name was "kindly shared" by acrylic acid, which has chemical formula CH 2 \u003d CH-COOH. Based on this compound and others, a very large number of fibers, polymers in liquid and solid form are obtained. In order not to delve into the wilds of chemical synthesis, since most readers will still not understand anything, let's say that the material from which the siding is made is in strict language scientific world called acryl-styrene-acrylonitrile. Another name is ASA plastic (the international name is ASA), and in the BASF concern this polymer is called in its own way - Luran S. It is completely clear that the siding is called acrylic, and not acrylic-styrene-acrylonitrile, for good reason, since sellers would have to develop diction, articulation and eloquence, and potential buyers would immediately be afraid of a tricky name.

ASA plastic is a thermoplastic polymer, and its melting and polymerization temperature is approximately the same as PVC. This allows co-extrusion to make compositions of PVC and ACA polymer bonded at the molecular level. What this gives, we will consider below.

What are the properties of thermoplastic ACA copolymer (hereinafter referred to as acrylic)? Why can it be used for siding?

- Acrylic has high rigidity, hardness and impact resistance.

- Acrylic retains its strength at temperatures up to 80-90°C, perfectly withstands short-term heating up to 100-110°C. When heated, unlike vinyl, acrylic does not emit any volatile compounds. It has virtually no odor.

- Acrylic products withstand low temperatures well. Acrylic becomes brittle only at temperatures from -25°C to -40°C (depending on the presence and amount of antifreeze additives).

- Acrylic is resistant to water, acids, diesel fuel, mineral oils. Detergents can be used to care for the acrylic coating.

- Acrylic has a density lower than that of PVC, it is in the range of 1.06-1.10 g / cm³.

- Acrylic has excellent biological resistance, fungi or mold will never settle on its surface.

- One of the main properties of the ACA copolymer is its resistance to ultraviolet radiation, it does not cause photodestruction. Thanks to this, acrylic can be painted in different, even bright colors that will not fade over time. In addition, opaque acrylic is a reliable barrier to ultraviolet light photons.

- Acrylic is very easy to process and recycle without emitting toxic gases, as is the case with vinyl. When processed, recycled acrylic practically does not lose its properties.

The combination of these properties determines the widespread use of the ACA copolymer. It is used to make exterior plastic parts of cars, housings for household appliances, sports equipment, parts of sea and river vessels, toys, plumbing items and other things. In the recent past, siding has also been made. Obtaining acrylic in the form of an ACA copolymer is a complex and expensive technological operation that is not available to all chemical concerns. Therefore, this material is much more expensive than PVC. This is its disadvantage. Perhaps the only one.

The most famous manufacturers of ACA copolymer (acrylic) are:

- Saudi Arabian company SABIC produces an ASA copolymer under the brand name Geloy ASA.

- LG Chemicals of South Korea manufactures this material under the name LG ASA.

- BASF in Germany produces an ACA copolymer called Luran S.

All manufacturers of quality acrylic siding purchase raw materials mainly from these companies, as they are of excellent quality.

What is acrylic siding

Now we offer, together with readers, to understand such a concept as acrylic siding. And the first thing I want to say is that 100% acrylic siding simply does not exist. If there was such a thing, it would cost such fabulous money that no one would pay attention to it. Let's take an example. One of the best siding manufacturers is the Canadian company Mitten, which gives a 50-year written warranty on its siding, provided that original components are used. They report absolutely honestly about their siding on their official website, calling it vinyl. True, in the description of their Sentry Mitten collection, which has the richest color gamut, it is indicated that the thickness of the panel is increased to 1.2 mm, and Acrylic Color Technology (a.c.t.) is used for color stabilization and management. That is, acrylic is mentioned, and it is used specifically for coloring and ensuring color fastness. But there is not a single word that the siding is acrylic.

Let's take now one of the leading Russian siding manufacturers - Tecos. In particular, the siding from the Tecos - Ardennes collection, which has the most intense color palette, is very interesting. What is written in the description of this collection on the official website (quote): “Please note that products in Arabica and Burgundy colors are produced using acrylic polymer, which has the highest degree of UV resistance and, thanks to this, additionally protects the color from fading.” By the way, we forgot to inform you that this refers to the section of the site "PVC siding panels". There is simply no such thing as acrylic siding.

If in any search engine give the request “Tecos acrylic siding” (any other is possible), then in a fraction of a second an impressive list of sellers will be issued, who, without any twinge of conscience, in the description of the product of this respected manufacturer, indicate acrylic in the “material” column. And this despite the fact that the manufacturer gave very correct information about his product. And unfortunately, a lot of sellers sin with such a violation as providing deliberately false information about a product. We decided to go further and find at least one certificate of conformity on the Internet, which would indicate that the siding is acrylic or ASA copolymer. And none were found. Where sellers proudly state that the siding is acrylic and there is a link to certificates, these documents state the following: “PVC wall panels of the Siding type, or just PVC siding. And nothing more.

The manufacturer's website states that this is acrylic siding, and the certificate of conformity says PVC siding. Who to believe?

It turns out that the statement that the siding is completely acrylic is not entirely correct? In other words, are the sellers lying? Yes, in fact it is. But we do not want to upset the readers of our portal and hasten to reassure that the ACA copolymer is really used in the production of colored siding as an outer layer. High-quality siding is painted throughout, including the outer acrylic layer, which itself does not fade under the influence of ultraviolet radiation, and also prevents its penetration into deeper layers. A thin outer layer of painted acrylic is enough to look presentable for decades and protect the full thickness of the panel. That's why good producer pursues a very noble goal - to save the buyer's money. And the name "acrylic" is a marketing ploy of sellers that does not detract from the merits of vinyl siding with an acrylic front layer.

How is acrylic siding produced? Considering that both PVC and ACA copolymer are thermoplastic plastics, then fundamental difference not in their extrusion. The outer layer is acrylic and the inner layer is vinyl. They are connected by co-extrusion, which makes the panel almost monolithic, which under no circumstances will delaminate. What links are included in the technological chain of siding production?

- Raw materials (acrylic and vinyl) are melted, each in its own bunker. This is to ensure that the components do not mix until the sheets are formed. And the temperature regime of one polymer may differ slightly from another.

- Dyes are introduced into the melts with special dispensers. In high-quality siding, coloring goes throughout the volume, so dyes are added to both PVC and acrylic. At the same stage, other components are introduced into the composition in strict accordance with the technology.

- The melt of compounds (thermoplastics) with the help of screws is fed to slotted dies, and PVC has its own die, and ACA copolymer has its own. The spinnerets have strictly calibrated holes, so the webs come out desired thickness. The spinnerets are positioned so that after the formation of the canvases it is possible to lay them one on top of the other while not completely cooled down. This is done in order to different materials securely "sintered" with each other.

- Next, the already formed two-layer canvas, which has not yet been completely cooled, must be given the desired texture and profile. To do this, the canvas first passes through the rollers that form the texture, and then is fed into the sizing mill, where the profile of the future siding is formed. This is done using shafts of the desired shape. The process of rolling through the shafts always goes with lubrication of their surface so as not to damage the workpiece.

- The final stage is cutting holes for fasteners and draining condensate, and then cutting a continuous web into segments of the desired size.

We have shown the technological process schematically, in fact it is much more complicated. The siding production equipment is high-tech and automated. It costs a lot of money and requires constant maintenance by highly qualified personnel and periodic replacement. The best manufacturers care about their reputation, so they replace their equipment with a clear regularity. But, of course, they do not throw the old into a landfill, but sell it on the secondary market. And who buys it? Of course, these are other companies that also produce siding. Only their siding will be somewhat different. Therefore, we will never get tired of telling readers that siding should be chosen only from the best manufacturers. Unfortunately, most of them are not domestic.

Video: Siding Extrusion Line

We will now try to answer main question, which was asked in the article: which siding is actually better - acrylic or vinyl. We use the information that we have read earlier and reduce everything for clarity in a tabular form. We will call the column in the table acrylic siding, but we already know that this is actually a vinyl “brother” with an outer layer of ACA copolymer (acrylic).

| Index | Vinyl siding | Acrylic siding |

|---|---|---|

| Image |  |  |

| Mechanical strength, wear resistance. | It is at a sufficient level, subject to literacy installation. It also depends a lot on percentage in the siding of secondary raw materials, the presence of additives and modifiers, as well as from the manufacturer. | Strength and wear resistance is largely determined by the characteristics of the vinyl base. Acrylic has high strength, elasticity and wear resistance. It also depends a lot on the manufacturer. |

| Chemical resistance | Inert to water, oils, alkalis, alcohols, technical gases, many acids found in everyday life. It is possible to use synthetic detergents, but only those approved by the manufacturer. | It has a slightly higher chemical resistance than vinyl. The range of detergents allowed for cleaning is wider. |

| Temperature resistance | It can be operated at temperatures from -40°C to +60°C. At low temperatures it becomes brittle, and at temperatures above +70°C it begins to “float”. Also, this indicator is highly dependent on the manufacturer and the presence of various additives in the composition. | Can be used over a wider temperature range than vinyl, but the overall durability of acrylic-faced siding is largely determined by the properties of the substrate. |

| Biological stability | High | High |

| Toxicity | When heated strongly, it begins to release hydrogen chloride. New siding may have bad smell, which quickly evaporates during operation. | Not toxic. Even strong heating does not lead to decomposition with the release of toxic components. |

| Dielectric properties | Does not conduct electricity, but is capable of accumulating static electricity, which leads to "sticking" of dust to the surface. Quality siding well-known manufacturers less prone to the accumulation of static electricity due to the introduced antistatic additives. | Does not conduct electricity. Much less likely to build up static electricity than vinyl siding. |

| fire safety | Low degree of flammability (G2 group). Does not support combustion. When the source of ignition disappears, it self-extinguishes. | |

| UV resistance | Vinyl is subject to photodegradation, but the use of special additives can slow down this process. | Acrylic is not subject to photodegradation, and its layer on vinyl backing is a reliable barrier against the penetration of ultraviolet rays. |

| Durability | Quality vinyl siding pastel colors able to last 50 years or more, and brighter shades 25-30 years. | The service life of vinyl siding with an acrylic outer layer is longer. This is especially true for samples that have a dark color and bright saturated shades. |

| Price | It is greatly influenced by the manufacturer and quality of siding. In general, it is significantly less than the more technologically advanced one. For 1 m² of vinyl siding, prices start at about 150 rubles. | More expensive than vinyl siding, but longer life over time eliminates unnecessary costs at a glance. For 1 m² of sideboard with an outer layer of ACA copolymer, prices start at 250 rubles. |

The table shows that more technologically advanced siding - with an acrylic front layer, is significantly more expensive. And its main advantage is that there is no photodestruction of the upper layer. Otherwise, the characteristics are very similar in many respects. So is it worth spending extra money when you can get by with a cheaper option? Our set of recommendations will be as follows:

- Both manufacturers and designers recommend using siding in soft pastel colors for home decoration. Such a cladding for a long time you will not get bored and the gradual photodestruction, which is expressed in the appearance of whitishness, will be almost imperceptible. It is known that pastel colors are obtained by adding white to some color. The process of burning out just manifests itself in the addition of white. In this case, the choice should be unequivocal - high-quality vinyl siding from a good manufacturer.

- If the owners decide to use siding in dark colors and rich shades in the decoration and want the facade not to fade for a long time, then, of course, the choice should be in favor of siding with acrylic coated face layer. True, at the same time it is necessary to measure the choice with your financial capabilities. The choice should also be only in favor of well-known manufacturers.

- If the house that needs to be lined with siding is located in the southern latitudes and is located in a place constantly illuminated by the sun, then the choice in favor of acrylic siding will be fully justified.

- If the siding is supposed to be washed frequently using household chemicals, then siding with an acrylic front layer will respond best to this. This may be in those regions where there is a large amount of dust and soot in the air due to natural causes or the location of some industrial facilities nearby.

- It happens that when facing houses, a combination of siding is made of light and dark tones to highlight architectural elements and emphasize uniqueness. Then you can buy vinyl siding in light colors, and acrylic siding for dark colors.

Unfortunately, not all domestic producers reach the quality of European and American colleagues. If in America vinyl siding began to be produced already in the 50s of the XX century, then in the post-Soviet space the traditions of production are far from being so rich. It is possible that the situation will improve over time, because we have learned how to make good pipes and window profiles. We learned how to make paving stones and facing bricks. Once the turn will reach the siding. True, analyzing the messages of the construction and repair forums, one can already find good reviews on Russian siding. We hope that every year there will be more of them.

A brief overview of prices for different types of siding

We felt that the topic of the article would not be fully disclosed without a review of siding prices in various online stores. We will try to consider different manufacturers, and vinyl siding, and with top layer from ACA copolymer (acrylic).

| Image | Name, manufacturer, panel size | Description | Price in rubles (as of March 2017) |

|---|---|---|---|

| Vinyl siding Kaykan (Canada), Prova series. Panel length 3660 mm, working width 230 mm, thickness 1.3 mm. | High quality vinyl siding painted with high quality dyes throughout. There are 15 panel colors available in the series. | 250 rub. for 1 panel, 22 pieces per pack. |

| Vinyl siding Kaykan (Canada), DaVinci series. Panel length 3810 mm, working width 200 mm, thickness 1.1 mm. | Vinyl siding in bright colors. Produced by co-extrusion, the outer layer is made using a special UV-protective compound Duraton. Available in 3 colors: Ivi Green (Green), Midnight Blue (Blue) and Colonial Red (Red). | 420 rub. for 1 panel, 24 pieces per pack. |

| Vinyl siding Mitten (Canada), Oregon Pride series. Panel length 3660 mm, working width 230 mm, thickness 1.02 mm. | High quality vinyl siding painted throughout. The series is available in 14 pastel colors. | 369 rub. for 1 panel, 22 pieces per pack. |

| Vinyl siding Mitten (Canada), Sentry Mitten series. Panel length 3660 mm, working width 230 mm, thickness 1.2 mm. | High quality co-extrusion vinyl siding in vibrant colors. The outer layer uses the exclusive Acrylic Color Technology, which gives the desired color and protects it from UV rays. The series is available in 10 colors. | 720 rub. for 1 panel, 22 pieces per pack. |

| Siding vinyl American Siding (Türkiye), Plus series. Panel length 3660 mm, working width 204.70 mm, thickness 1.1 mm. | Vinyl siding available in 10 pastel colors. | 150 rub. for 1 panel, 25 pieces per pack. |

| Siding vinyl American Siding (Türkiye), Platin series. Panel length 3660 mm, working width 204.70 mm, thickness 1.1 mm. | Vinyl siding in bright colors. Available in 2 colors: Brick (Tile) and Pine-Green (Pine green). | 210 rub. for 1 panel, pack of 25 pcs. |

| Siding vinyl American Siding (Türkiye), Private series. Panel length 3660 mm, working width 204.70 mm, thickness 1.1 mm. | Laminated vinyl siding. Available in 2 colors: Antic Brown (Brown), imitating wood (block house), as well as Paciffic Blue (Blue). | 350 rub. for 1 panel, 25 pieces per pack. |

| Vinyl siding Tecos (Russia), series "Natural wood effect - rounded timber", panel length 3660 mm, working width 203 mm. | High quality vinyl siding imitating timber. It is represented by two types: "Canadian oak" and "Lebanese cedar". | 320 rub. for 1 panel, 18 pieces per pack. | |

| Vinyl siding Tecos (Russia), "Ardennes - ship timber", panel length 3660 mm, working width 230 mm, thickness 1.2 mm. | High quality vinyl siding painted in vibrant burgundy. | 260 rub. for 1 panel, 18 pieces per pack. | |

| Vinyl siding Alta Profile (Russia), Canada Plus series, panel length 3660 mm, working width 230 mm, thickness 1 mm. | Vinyl siding with an ACA copolymer outer layer. Presented in 12 colors. | 250 rub. for 1 panel, 20 pieces per pack. |

The choice of siding is huge and the above table does not reflect even a hundredth of what can be found on the building materials market. In any case, in each individual region, some types of siding will be available, but others will not be available. Or you will have to order in advance and wait for a while. The main thing is to make a choice, and this is very difficult.

Conclusion

Despite its high price, siding with an ACA copolymer (acrylic) coating in the front layer is still actively moving into the market. Every year its share in the total number is growing. But, as we have already found out in the article, its use must be reasonable and economically justified. We, as consumers, should be pleased that more and more manufacturers are using new technologies in their products. It still affects the price, and in our favor.

And finally, it's time to answer the main question of the article: which siding is better - acrylic or vinyl? And perhaps the best answer is that the best is the siding that lined the facade of your house!

Video: How to choose vinyl siding. Pros and cons of finishing material

Video: How to choose siding

Those who decide to buy siding for facade decoration in Belarus should pay attention to top manufacturers from Russia and Belarus. They offer a worthy alternative to foreign analogues, often not inferior to them in quality. At the same time, the price of siding will be much more attractive than for the products of Western firms.

We present you five leading manufacturers of siding panels, deservedly popular in the Belarusian building materials market.

Siding Docke

This is a product of the Russian manufacturer Döcke Extrusion. The company has been on the market since 2005. The company supplies products to the regions of Russia, as well as to the markets of Belarus, Ukraine, Kazakhstan, Uzbekistan, Bulgaria and Moldova

The company's products are represented by a fairly wide range. This is not only siding and additional elements, but also the whole range of materials that allow you to complete the finishing of the house.

Docke offers the following ranges of vinyl siding:

- D4,5 Dutchlap - "Ship board" - panels horizontal fastening, outwardly resembling a ship beam. The panel is an imitation of two boards, one above the other.

- D5C - "Herringbone" - horizontal fastening panels, reminiscent of the structure of " ship plank”, but differing in the shape of the profile.

- "Block house" - horizontal panel, imitating the rounded shape of a log.

- S7 - Vertical siding - panels with an unusual, vertical way mounts.

Döcke siding colors represented by "appetizing" pastel colors, which have the appropriate names: "banana", "peach", "caramel," ice cream ", etc. - about 16 shades in total. Externally, houses with such decoration look fresh and bright enough.

Siding from Döcke Extrusion is popular due to its relatively low price and interesting texture and color solutions.

However, some consumers note the following disadvantages:

- come across parties with poor quality coloring (erased);

- low reliability of additional elements;

- due to the fine structure of the panel, dust accumulates and is difficult to remove, which requires additional maintenance;

- prone to fairly rapid burnout.

In addition, the quality of raw materials used for the production of panels, in last years decreased somewhat.

vox siding

The international Polish-Belarusian company Profile VOX has been producing furniture and building materials since 1992. Vinyl siding produced under the VOX brand can be bought in Belarus, products are also imported to the countries of Eastern Europe and the European Union, the Asian region, as well as to Africa.

Advantages of VOX siding:

- At fairly affordable prices, the quality of the building material, in principle, is able to satisfy the aesthetic and practical needs of homeowners.

- Installation of panels is facilitated by a well-thought-out locking system. The company also offers a full range of accessories for installing siding.

- The special shape of the edges creates enhanced wind protection.

- The textured grooves of the panels provide water runoff and spontaneous cleaning of the surface under the influence of wind.

- The material has a sufficient degree of strength and resistance to sunlight.

VOX siding will appeal to connoisseurs of traditional color schemes who prefer soft shades.

VOX panels are available in the following series:

- NATURE - within the framework of the series, a high-quality imitation of the color and texture of valuable tree species is presented: various varieties of oak, as well as pine.

- UNICOLOR - a series represented by textured panels made in pastel colors. The color range of the series is diverse.

The disadvantages of Vox siding include low resistance to fading, a fairly high cost, compared, for example, with the same Yu-layer by 25-30%. Just as often, when selling, they say that Vox is of Polish origin, to cheat quality and price, although the main factories are in Belarus. Unable to exchange for defects.

Siding Alta profile

Alta-Profil, founded in 2004, is the first manufacturer of vinyl siding in Russia. At present, its products occupy one of the leading positions in the markets of the Russian Federation, Belarus and other post-Soviet countries.

The advantages of Alta-Profile siding include:

- Compliance of products with the requirements of GOST. The Institute of Chemical Physics of the Russian Academy of Sciences took part in the development of the siding.

- Materials designed with climate in mind middle lane well tolerates temperature changes and severe frosts.

- The color palette of Alta-Profile siding is bright and extremely diverse.

Buyers note the good quality, ease of installation, the availability of all the necessary additional materials that allow you to quickly and efficiently produce all types of facade finishes, convenient compact packaging of the siding, which facilitates transportation.

Finishing material is presented in the following series:

- "Alta Siding" is a classic horizontal siding that imitates a wooden texture and is presented in 10 tones traditionally used for home decoration.

- "Kanada Plus" - panels with increased strength and resistance to temperature extremes.

- "Blockhouse" - siding, imitating the relief of rounded logs, is presented in a single-fracture and double-fracture version.

- "Quadrohouse" - panels of vertical fastening.

- "Alaska" - an improved form of siding, created on the basis of innovative technologies. Tolerates frost well.

With all the advantages of this brand, the price of siding for it seems to be slightly overpriced. This option is suitable for lovers of bright, creative facades.

Siding U-layer

The U-Plast company is a Belarusian manufacturer of vinyl siding, which sells its products in the country, as well as in the post-Soviet space - in Russia, Ukraine, Kazakhstan. Since the summer of 2018, the company claims that it has begun supplying goods to the European market.

Among the main advantages of the products of this company can be called:

- Affordable prices.

- A wide variety of design solutions: siding panels are a naturalistic imitation of precious woods, there is a unique series that imitates neat brickwork.

- Color fastness - for 2018, U-Plast uses dyes and pigments from MasterTec (Germany).

- Ease of installation at positive temperatures.

Among the shortcomings, there is an opinion among the installers of the "old school" that they worked with the first versions of siding - this is the brittleness of the material and the tendency to burn out under intense exposure to ultraviolet radiation.

"U-Plast" offers customers the following series of vinyl siding:

- Timberblock - panels imitating the color and structure of precious woods: oak and ash.

- Timberblock spruce - a special series, the panels of which reproduce lumber made from various spruce species.

- Ship timber - a series represented by a variety of delicate pastel shades.

- Block house - imitation of logs, made in various light colors brown colors - beige, cream, coffee.

- Stone House - a series that imitates brickwork and is rich color palette characteristic of this material.

Vinyl panels from U-Plast are suitable for those who want to give their country house a neat modern look and at the same time strive to save money.

FineBer siding

Siding of this brand is produced by the Terna Polymer company, which specializes in the manufacture of materials for facade and interior decoration.

Panels from this manufacturer have a number of advantages over products from other companies:

- The company's products undergo strict laboratory quality control, fully comply with the requirements of GOST and the American ASTM quality standard.

- The siding has a unique texture that exactly repeats the texture of wood, while having all the advantages of a vinyl material.

- The colors repeat the natural shades of nature, a house with such a finish organically fits into both the countryside and the urban landscape, looks noble and solid.

- The price of FineBer siding is the most competitive on the market.

The range of siding is presented in the following series:

- "Standard" - horizontal siding of a traditional form, made in soft classic colors.

- "Standard Plus" - the series is distinguished by more saturated shades, mainly imitating valuable tree species.

- "Block House" - panels with a rounded profile, mostly light noble shades.

- "" - a line of budget, but durable and high-quality siding made especially for Belarus.

Such siding is suitable for connoisseurs of traditional design solutions, who value nobility and excellent quality, but do not forget about savings.

Summing up

5th place Vox59%

The price (5.3/10) is quite expensive, for the price and quality they say that it is Polish, although the main factories are in Belarus.

Quality (5.6/10) - brittle, can smell like paint and fade in 2-3 years, well, if you're lucky, you come across both good and bad.

Appearance (6.5/10) is peculiar, but it is difficult to call it the most beautiful.